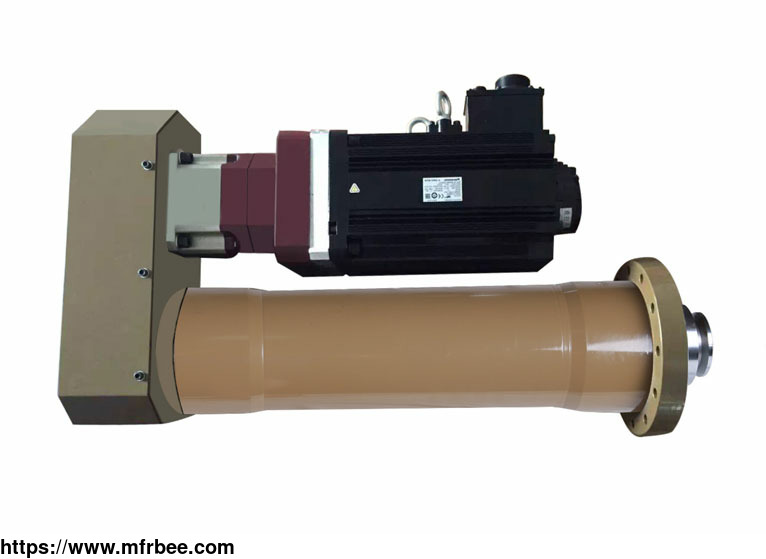

TYD TURN-BACK SERIES SERVO ELECTRIC CYLINDER Free Quote

Product Quick Detail

- FOB Price

- USD $180,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Ningbo

- Packaging

- N/A

- Delivery

- 45 Days

Specifications

TYD series servo electric cylinders can work in a harsh environment for a long time without failure, and achieve high-intensity, high-speed, and high-precision movement. With smooth movement and

low noise, the unique anti-rotation function ensures the high-precision position control and high safety of the equipment. The best alternative to hydraulic cylinders and air cylinders. The compact

electric cylinder can completely replace hydraulic cylinders and cylinders with the advantages of being more environmentally friendly, more energy-saving, and cleaner. It is easy to connect with

PLC and other control systems for high-precision motion control.

Principle Of TYD Turn-back Series Servo Electric Cylinder

The servo electric cylinder is a modular product that integrates the servo motor and the ball screw. It converts the rotary motion of the servo motor into linear motion. At the same time, the best

advantages of the servo motor: precise speed control, precise revolution control, and precise torque control are transformed into precise speed control, precise position control, and precise thrust

control; a new revolutionary product with high-precision linear motion series. And the fast electric cylinder is widely used in material handling, machining, and manufacturing, high-precision

fields such as aerospace test equipment, six-degree-of-freedom simulator, robots, injection machines, mold control, valve control, precision machine tool, and automobile manufacturing equipment.

Features Of TYD Turn-back Series Servo Electric Cylinder

Thrust range: 10kg-10 tons.

The stroke can be up to 3m, and the working system is 100%.

Speed can reach 1,000mm/s.

Imported grinding-grade ball screw, and high efficiency without self-locking.

Equipped with imported servo motors of various brands.

Realize the closed-loop servo control by adding the grating ruler, and the control accuracy can reach 0.01mm.

Precision control thrust and thrust accuracy is 5%; the control accuracy is 1% by adding the pressure sensor.

Precision control speed, high performance, and high and low-speed performance.

Thrust can be maintained at any position.

High dynamic response time, and high acceleration.

High rigidity and impact resistance.

Super long service life, easy operation and maintenance, and low noise.

Low maintenance cost.

In the complex environment, the servo electric cylinder only needs regular grease lubrication without any maintenance and replacement of the wearing parts, which will reduce the after-sales service

cost when compared with the hydraulic system.

The Flexibility Of TYD Turn-back Series Servo Electric Cylinder

A flexible installation configuration is available. The series of installation components: installation of the front flange, rear flange, side flange, rear hinge joint, trunnion installation, and

guide module; The high speed electric cylinder can be installed in line or parallel with the servo motor; can be added with different kinds of accessories: limit switch, planetary reducer, and

pre-load nut; AC brake motor, DC motor, stepper motor, and servo motor of various manufacturers can be selected for a drive.

Contact us to buy servo hydraulic machine or know more.

- Country: Afghanistan

- Address: No. 1, Wenxia Road, Lanxia Street, Yuyao City, Ningbo City, Zhejiang

- Contact: tian yu