What Is Stick System Curtain Wall?

A stick built curtain wall system refers to the method of construction by which the curtain wall is assembled on-site, piece by piece. The manufacturer delivers each individual component; glass,

mullion, spandrel; and workers assemble the sticky system curtain wall directly on the structure.

Project Stick System Curtain Wall Details

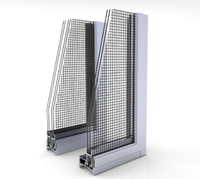

CSCW-N180 Stick Curtain Wall

Stick curtain wall CSCW-N180 is an efficient and reliable curtain walling stick system.

Stick Curtain Wall Installation

Stick and unitized curtain wall system's elements are pre-farbricated on factory, then shipping to on-site via kit form. The cast in plates were firstly embeded during the concrete works. Then

the installing workers will fix the mullions and transoms to the cast in plate via brackets. The glass panel will be put in position accordingly, workers will fix the aluminum adaptors to press

on the glass edge bewteen the panels, so the glass will be strong enough to fix on the frame. If for visible frame curtain wall stick, people will add a decoration capping between the glass seam,

the shape and design will be creative. The last but the important, the waterproofness for stick curtain wall is mainly via caulking, workers have to do caulking with weather sealant and backer

rod.

Curtain Wall Stick System Advantages

1, Flexibility; Different with unitized curtain wall, stick curtain wall's parts are pre-farbricated in factory, but panel assembling on site. So it can offer more flexibility to installation

workers based on on-site condition.

2, Cost competitiveness; Due to the relatively simple in structure, and less production process in factory, the product cost will be lower than unitized curtain wall. Because of the kit form

shipping for stick curtain wall, stick curtain wall can attain lesser containers, and cheaper logistics cost.

Stick Type Curtain Wall Applications

Stick aluminum curtain wall is mainly used for low level building, like shopfronts glazing or high rise panel for residential or commercial building.

Elimination of Water Penetration:

Water penetration is the essential function of a mask, it may not be possible to convey an impermeable seal curtain panel system, so two levels of containment are placed.

The upper level where water is conserved, if it fails in the secondary stage, where a course of drinking contaminated water is to be offered.

Air permeability:

This function is an environmentally friendly for reducing carbon dioxide emissions due to the rate of heat loss or gain in the external and internal environments.

Resistance to the wind, thermal, and acoustic motion:

The wall cladding system transfers wind works to the ground of construction acting as direct support.

Building cladding programs made of large panels are often unilateral therefore the level of each floor helps in the air load on a construction.

A mask requires a strict thermal insulation function to reduce energy consumption and CO2 emissions- insulating supplies in each opaque and transparent area.

Acoustic insulation between the inside and outside environments is essential in city-centric buildings. Large-scale structural elements have excessive acoustic insulation such as masonry or

concrete structures.

Solar Level:

This contribution can reduce the selective solar management coating on one of several glass surfaces.

Solar radiation of different wavelengths is allowed to traverse through the layer selectively, the visible wavelength of light is allowed to move freely than the ultraviolet wavelength.

For example, ultraviolet radiation can cause erosion of materials or areas of exposure & a UV-inhibitor film can be applied to the surface of the glazing.

Unitized VS Stick Curtain Wall

Facade size:

The larger the size, the more suitable option is unitized. Giving a rule of thumb, Sola advises unitized for more than 5,000 square meters, and stick if the facade is less than 3,000 square

meters, as there isn’t not enough space to achieve the economy of scale to justify unitized.

Degree of repetition:

If the floor height is constant and the distance between mullions is repetitive, then breaking the facade into units of a similar size—as is the case with unitization—and prefabricating them in

the factory makes sense.

Shape and dimensions:

Taller buildings above six floors are more suitable for unitized systems, but a low, extended building is a better fit for stick.

Planarity:

If dealing with flat, vertical walls, the on-site assembly of a stick system will be best. But once slope, three-dimensional slopes, and the like are added, the preference shifts to unitized.

According to Sola, the same applies for penetrations. The more brackets required for external sunshades, for instance, the more prefabrication is favored.

Allowance for structural movements:

If the project is in a seismic zone and/or if shear or floor-to-floor movements are to be expected, then the ideal choice is unitized.