BMC/SMC Insulation

Specifications

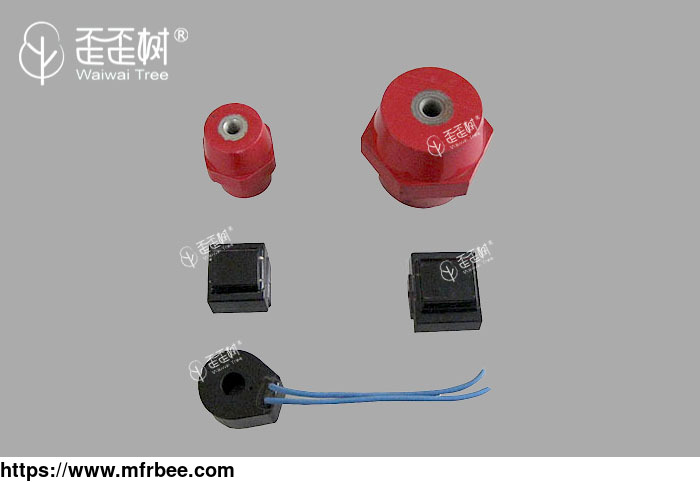

SMC/BMC Insulation

High-strength, wear-resistant, fire-resistant, color BMC material for medium and low voltage insulators such as SMC Insulated. Typical applications are switch boards, busbars, switchgear, etc. BMC

(Body Molding Plastics) is a blend of glass fiber reinforced polyester resin and chemical mineral materials with special properties such as electrical insulation, low density, high mechanical

strength and fire resistance. High sealing, high safety, low process and low cost.

What Is Sheet Molding Compound Insulation and How Does It Work?

Sheet Molding Compound (SMC) insulation is a type of thermosetting material made from a blend of various components such as resins, glass fibers, and fillers. SMC insulation is used in various

applications where high-strength and electrical insulation properties are needed. SMC insulation is formed by compression molding in a hydraulic press, which cures the material into a solid form.

The resulting product is a rigid, durable, and electrically insulating material that is ideal for use in electrical equipment and systems.

What Are the Benefits of Using SMC Insulation?

SMC insulation offers many benefits over other insulation materials. SMC insulation has excellent electrical insulation properties and is highly resistant to moisture, chemicals, and temperature

fluctuations. Additionally, SMC insulation is lightweight, making it ideal for use in applications where weight is a concern. The material is also easy to manufacture, which makes it a

cost-effective solution for many industries.

Common Applications of SMC Insulation

SMC insulation has a wide range of applications across various industries. Some common applications include electrical enclosures, switchgear, transformers, and motors. The material is also used in

the automotive industry for parts such as bumpers and hoods. Additionally, SMC insulation is used in the construction industry for roofing and cladding panels.

SMC Insulation Installation

SMC insulation is typically installed by mechanically fastening it to the substrate using screws or bolts. The material can also be bonded to the substrate using adhesives. The installation process

should be performed by trained professionals to ensure that the material is installed correctly and safely.

Environmental Considerations of SMC Insulation?

SMC insulation is an environmentally friendly material compared to other insulation materials such as fiberglass. SMC insulation is made from recyclable materials, and it is also a low-emitting

material, meaning that it does not release harmful VOCs (Volatile Organic Compounds) into the air. Additionally, SMC insulation has a long lifespan and requires minimal maintenance, which reduces

its environmental impact.

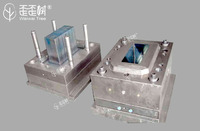

Establithd in 2010 and located in Chengnan Development Zone, Luothe Tow, Huzhou City, Zhejiang Province, Zhejing Aobang Technology Co. L.d. not only has a mature and extensive prodution line of

SMC/BMC compound but also possesses many refined testing laboratoies in the industry. Whether at home or abroad, Zhejiang Aobang Techmnology Co. Ltd. can manufacture top-qulity SMC BMC composites

with advanced mold making concepts and technologies.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,G20,Middle East,Oceania

- Founded Year: 313218

- Address: No.62,zhidailang,sha village,luoshe town, deqing,huzhou city, zhengjiang, China.

- Contact: Coffee Tu