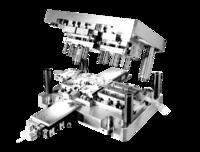

Plastic Connector Mould with Brass Molding Inserts

Product Quick Detail

- Place Of Origin

- Shenzhen

- Minimum Order

- 1

- Packaging

- Carton

- Delivery

- 30-60 days

Specifications

In order to meet the needs of installation and connection, or to increase the strength of the plastic part, suitable metal parts are designed to insert into plastic molding parts, making an

integrated products of both metal and plastic.

The connector is designed with brass insert, it is a good insulator with better strength, so it is applied for electronic and electrical power components, machinery and equipment installation.

High-quality brass inserts for injection molding

This mold is multi-cavities 1*2. The insert positioning block for the copper can be taken out and put in easily from the cavities. The brass insert was preheated to ensure a uniform temperature in

the mold cavities.

Basic Information for Connector with Brass

Plastic Connector Mould Specification

Description Connector with Brass

Plastic material ABS

Mould dimension(mm) 300*300*410 mm

Mould weight (T) 350 kgs

Mould cavity & core steel H13

Nos of Cavity 1*2

Manufacture time (day) 30 days

Mould life ≥50,0000

Molding cycle (S) 35 S

Cooling line connector type quick coupling

Mold Characteristics insert positioning block

Benefits of Plastic Connector Molded with Brass Insert

Plastic molding part with metal material insert provides you additional functions, you can obtain great advantages including:

It is of electric conduction with brass insert for electronic devices electrical equipment.

To design with screw thread section on the metal, it can be installed to devices and equipment very conveniently.

With metal insert, it enhances the strength of the plastic molding connector.

It is of electrical insulation and heat insulation for safety sake.

With low-level noise.

How To Design A Connector With Metal Insert

Select metal materials with a small coefficient of thermal expansion as inlay materials, such as brass, aluminum, aluminum alloy, etc.

The metal design shall not have sharp corners, and shall be properly rounded to improve the plastic strength. The surface of the insert should preferably be provided with exquisite rolling patterns

or grooves to increase the friction.

The plastic thickness around the metal insert shall be sufficient. For example, the plastic thickness around the insert is "h", the outer diameter of the metal insert is "D", the plastic

thickness for the aluminum insert should be h ≥ 0.8D, and the plastic thickness for the brass insert should be h ≥ 0.9D.

Green Vitality Industry is a professional injection molding factory in various industries since 1993. We provide metal insert moulding, plastic insert moulding, brass molding inserts, metal insert

molding, injection mold and etc. Want to know more, contact us.

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:

- Address:101#, Building C, North Yongfa Hi-Tech Industrial Park, Shajing Road, Shajing Town, Bao'an District, Shenzhen, China

- Contact:Susan Qin

Other products from Green Vitality Industry Co., Limited

Relate products of Plastic Connector Mould with Brass Molding Inserts

Plastic Connector Mould with Brass Molding Inserts

In order to meet the needs of installation and connection, or to increase the strength of the plastic part, suitable metal parts are designed to insert into plastic molding parts, making an integrated products of both metal and plastic. The connector is designed with brass ...

Professional Injection Molds Maker For Connectors And Mould Makers Plastic Motorcycle Mold

Professional Injection Molds Maker For Connectors And Mould Makers Plastic Motorcycle Mold sisazhietyize Material Details SKD11. SKH51. SKD61.ASP CARBIDE..More materials Processing technology Lathe processing / hardness processing / grinding machine processing / surface ...