Shot Blasting Machine

Specifications

Shot blasting machine is an effective method to remove the surface contaminant, clean and roughen a smooth surface before applying a primer or coating. Shot blasting equipment is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, shipbuilding, rail, and many others.Shot blasting machine is a non-standard machine, all the detailed parameters are tailored according to customer object items detailed conditions and customer requirements. Whether wheel blasting or air blasting, our products can meet your demands. As an expert automaticshot blasting machine manufacturer from China with 45 years' experience, QingGong Machinery has sold more than 4000 sets of shot blasting equipment all over the world. Contact our engineer for competitive shot blasting machine price.

History ofShot Blasting Machine

Industry: Cleaning, Mechanical, Metal, Metallurgy, Metal casting.

Application: Automotive industry, Construction industry, Windpower industry, Railway industry, Foundry- forging industry, Shipyard, Mould industry, Pipeline cleaning industry, Electric industry, Stone industry.

Inventor: Benjamin Chew Tilghman

Invented: October 18th, 1870

Benjamin Tilghman was a general in the army and saw the effect of wind-blown sand on windows in the desert. The might be the basis of his shot blasting machine invention.

On October 18.1870, Tilghman filed a patent, titled “Improvement in cutting and engraving stone, metal, glass, etc”, in the US(US paten 108,408), detailing many unique applications of the technology, such as sharpening files, carving bottles, cleaning boilers or turning. The wood grain comes out. Later that year, a patent was issued in the UK.

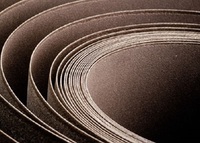

Shot blasting is a technique in which a selected class of abrasive particles is used to do surface preparation, that is, remove material from a surface at a high speed (65-110m/s) corrosion rate. It is the operation of forcing the abrasive stream to the surface under high pressure to smooth the rough surface, roughen the smooth surface, and shape or remove surface contaminants. A pressurized fluid (usually compressed air), or a centrifugal wheel is used to propel the blast material (commonly referred to as the medium).

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,Middle East,Oceania

- Founded Year: 2002

- Address: No.8, North Road, New & High Industrial Zone, Zibo, Shandong,

- Contact: Guizhen Zhu