Screw Barrel

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

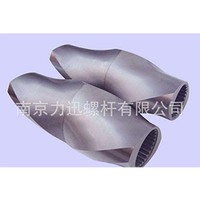

Thetwin screw barrel manufacturer, Lexun, provides different types of screw barrel, including open barrel, closed barrel, open side barrel and liquid barrel for your needs.

Screw Barrel Manufacturer

Twin Screw barrel Diameter:

φ20 mm ~φ300 mm

Twin Screw barrel Properties:

Wear-resisting, Corrode-resisting, Durable

Nanjing Lesun Screw Co.,Ltd specialize in the manufacture of parallel co-rotating modular Barrel, involving various types of twin screw barrel ranging from Ø20mm to Ø300mm. After more than 10 years of luxuriant development, our screw barrel factory now owns several sets of advanced CNC machines and special processing equipment for manufacturing screw.

Screw barrel plays an important role inside extruder. Barrel contain screw element. Screw element works inside Barrel. Barrel and screw elements are corporated each other to support extruder process smoothly.

To extend lifetime of twin screw barrel, anti-brasion and anti-corrosion performance are crucial.Lesun twin screw barrel is mainly with material of Bi-metal liner + 45# steel cylinder; N00 nitriding steel; H6 or D11. Furthermore, High wear-resisting and high corrode-resisting HSS-PM and other special steel material are also available.

Asone of professionalscrew barrel manufacturers, Lesun can supply standard screw barrel such as standard extruder screw barrel and side feed barrels, closed screw barrels, open screw barrels, combi screw barrels for many overseas extruder brands like Coperion, Leistritz, Berstorff, Toshiba, JSW, Kobe, APV, Maris etc.

Is screw barrel cleaning a challenge? Cleaning your twin screw barrel doesn't have to be a dirty or dangerous job if you use the right extruder barrel cleaning tools to clean screw and barrel between jobs.

Screw Barrel for Sale

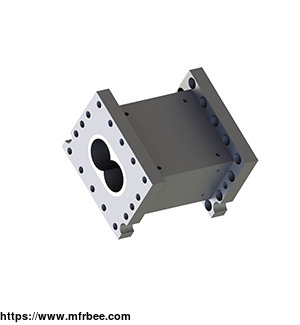

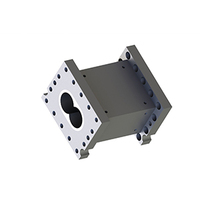

Extruder Closed Screw BarrelExtruder Closed Screw Barrel

Extruder Open Screw BarrelExtruder Open Screw Barrel

Extruder Side Open Screw BarrelExtruder Side Open Screw Barrel

Extruder Feed BarrelsExtruder Feed Barrels

Extruder Side-Feed BarrelsExtruder Side-Feed Barrels

Extruder Side-Feed BarrelsExtruder Side-Feed Barrels

Extruder Combi BarrelsExtruder Combi Barrels

Processing Characteristics of Twin Screw Barrel:

1. Suitable suggestion on material to ensure components performance and extend lifetime of twin screw barrel.

2. Professional technical team can provide surveying and mapping support.

3. All components of twin screw and barrel are finished by CNC machine.

4. The screw barrel suppliers' sophisticated quality managment system ensure superior quality.

Screw and Barrel Wear Tolerances

The screw barrel manufacturers control screw and barrel wear tolerance in a critical scope for all plasticating applications. The screw and barrel wear tolerances for the diameters on the drive shank will be typically +/-. 001” and the lengths will be +/- 1/32” (. 030”).

If you want to know more kinds ofextruder components, please visit our website.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:

- Founded Year:2004

- Address:Zhang Qiao Industrial Zone Lu Kou street, Jiang Ning District ,Nanjing city,211113,Jiangsu Province,China.

- Contact:lesun Screw

Other products from NANJING LESUN SCREW CO.,LTD

Relate products of Screw Barrel

Camstar Mauser X Matte .177cal, 4.5mm Break Barrel Air Pistol Introducing the Camstar Mauser X Matte Air Pistol, a fantastic option for beginner shooters and enthusiasts alike. This air Pistol offers an affordable entry point into the world of shooting ...

VXO precision ball screw are ideal for large fabrication machines in injection molding, pressing and metal fabrication. They move heavy loads in horizontal and vertical axes accurately and safely, while providing long and reliable life with minimum maintenance. Our standard ...

The Barrel Blast Machine line provides outstanding performance and reliability. Designed for foundry, forge and heat treat requirements. The Barrel Blast Machine or rolling drum shot blasting machine is the ideal solution to clean small to medium size parts that would normally ...