Conveying Screw Element

Specifications

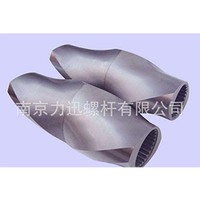

The main function of the conveyingscrew element is to help the material forward in the cylinder, and it will determine the conveying speed according to the size of the lead. The larger the lead, the faster the conveying speed. Conversely, the smaller the lead, the slower the conveying speed. Conveying elements can be divided into kneading elements and non-kneading elements. kneading and non-kneading can be selected according to the shape of the material.

Conveying Screw Element Manufacturer

Extruder Screw Elements Dimensions:

φ20 mm ~φ300 mm

Extruder Screw Elements Properties:

Wear-resisting, Corrode-resisting, Durable

Introduction to Extruder Screw Element for Sale

The conveying screw element is a self-sweeping typeextruder elements, open longitudinally and closed laterally, which has strong conveying effect. Short material residence time and good self-cleaning property enable it to establish high pressure within a short axial distance.

The conveying screw component is mainly a thread structure, and its function is to convey the material and give the material a certain thrust so that the material can overcome the resistance encountered in the flow channel. Conveying screw elements are currently the most popular extruder screw elements, with a strong transport function, short residence time and good self-cleaning properties.

Lesun can supply standard conveying extruder screw element for many overseas extruder brands like Coperion, Leistritz, Berstorff, Toshiba, JSW, Kobe, APV, Maris etc.

Conveying Screw Element for Sale

Single-flighted Screw ElementsSingle-flighted Screw Elements

Double-fighted Screw ElementsDouble-fighted Screw Elements

Triple-fighted Screw ElementsTriple-fighted Screw Elements

SK Screw ElementSK Screw Element

Buss Type Screw ElementBuss Type Screw Element

SFV Screw ElementSFV Screw Element

Processing Characteristics of LESUN Extrusion Screw for Sale:

1.Suitable suggestion on material to ensure components performance and extend lifetime of conveying screw components.

2.Professional technical team can provide surveying and mapping support.

3.All extrusion screws are finished by CNC machine.

4.Sophisticated quality managment system ensure superior quality.

5.All component materials are supplied by professional material supplier, and element and metallographic analysis are carried out to ensure that the raw materials are safe;

6.The internal spline is 100% checked with a spline plug to ensure the interchangeability of the conveying screw components;

7. Alltwin screw extruder screw elements are finished by CNC grinding

8. Professional technical team can not only provide timely and accurate sample mapping design, but also provide technical services in component combination.

9. The perfect modern management system ensures that the conveying screw elements received by the customers are 100% qualified, and the quality of each component is traceable.

Contamination in a continuous process like extrusion can take a profitable piece of business to un-profitable in no time at all. So cleaning is very important. Take a look at extruder screw cleaning and processes, it will help a lot!

If you want to know more kinds ofextruder machine spare parts, please visit our website.

As anextruder screw manufacturer, we will do our best to meet all the needs of customers.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:

- Founded Year:2004

- Address:Zhang Qiao Industrial Zone Lu Kou street, Jiang Ning District ,Nanjing city,211113,Jiangsu Province,China.

- Contact:lesun Screw