FSW Products

Product Quick Detail

- FOB Price

- USD $500.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Wooden pallet, carton

- Delivery

- 1-7 Days

Specifications

Cheeven, as one of the most professional friction stir welding suppliers, is committed to the development, application and promotion of FSW products & friction stir welding technology. Pro in FSW

friction stir welding, Cheeven has rich experience in R & D and the production of FSW products, especially in the design and manufacturing of battery trays, electric cabinets, motor products and

aluminium alloy water cooling parts of new energy vehicles. After the production of FSW products, the company will conduct professional ultrasonic nondestructive testing and provide FSW products

testing reports.

As one of the leading friction stir welding suppliers, Cheeven has independently developed additive friction stir welder for sale with upper and lower double heads and intelligent visual friction

stir welding technology, which is at the leading level in all the friction stir welding suppliers.

FSW FRICTION STIR WELDING PRODUCTS FOR SALE

Battery Tray Holder

Battery tray, suitable for new energy vehicles, aluminum alloy materials, integral casting or aluminum profile welding, heat dissipation profiles, customized according to the picture.

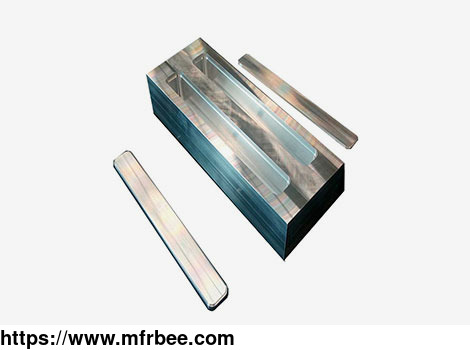

Water Cooling Plate

New energy vehicle battery water cooling and heat dissipation, aluminum with strong thermal conductivity, fast water cooling and heat dissipation, aluminum alloy material, not easy to corrode,

customized on demand.

Battery Cold Plate

Aluminum alloy, stainless steel and other materials, suitable for new energy vehicles, semiconductors, medical equipment, aerospace, with a variety of processing technologies, support for drawing

customization.

Photovoltaic Cooling Panel

Aluminum alloy material water cooling, cold aluminum plate, water cooling plate, trial photovoltaic system industry, heat dissipation profile, friction stir welding process.

Medical Equipment Water Cooling Plate

High quality, aluminum alloy, water cooling radiator, medical equipment water cooling plate, heat dissipation profile, medical equipment, for medical equipment.

Copper Water Cooling Plate

Cold copper plate, suitable for medical equipment, semiconductor industry, excellent thermal conductivity, heat dissipation material.

Semiconductor Cooling Plate

Semiconductor water-cooling plate, suitable for semiconductor equipment, the main material is aluminum alloy, stainless steel, used in new energy vehicles, semiconductors, medical equipment,

aerospace, various machining technologies

Water-cooled Motor Housing

Cheeven is pro in producing cooling/cold channel, water colored aluminum motor housing, aluminum alloy motor housing, main processes include aluminum extrusion, friction stir welding water channel,

suitable for new energy vehicles, heat dissipation profiles.

Water Cooling Controller

Aluminum vehicle control unit shell, electric vehicle main drive controller, main processes include die casting, friction stir welding water channel, heat dissipation profiles, customized drawings,

electric control box shell.

Aluminum Alloy Wheel Welding

Automobile friction stir welding FSW aluminum rim, automobile wheel hub with good noise function, the main materials are aluminum alloy, stainless steel, suitable for automobile field.

FRICTION STIR WELDING PROCESS

The friction stir processing can be summarized as follow.

1. First both the work plates are clamped together same as in the butt joint. Both plate's weldable surfaces are in contact with one another.

2. Now a rotating tool pin is inserted into workpieces at the interface surfaces until the tool shoulder touched the workpiece. This will deform the material plastically due to heating by friction

force. This is a state of the joining process in which, inter-molecular diffusion will deform the material plastically due to heating by friction force.

3. Now the rotating tool is moving forward along the joint line. This will form a joint behind the friction stir welding tool.

4. The tool continuously moves unlit the whole weld is formed. After the joining process, the friction stir welding tool is separated from the workpiece. The hole created by the tool pin remains in

the welding plates.

Its work can be clearly understood by the following friction stir welding video.

FRICTION STIR WELDING ADVANTAGES

It is a solid state welding so does not use flux, filler metal etc.

The microstructure change of the heat-affected zone of the welded joint is small. The residual stress is relatively low, and the welding workpiece is not easy to form.

FSW can be used to weld both similar and dissimilar metals.

Large welding seam design, which can be welded in all directions.

Fine grain size and quality weld can be obtain by this process.

The stir welding process is convenient to realize mechanization, low energy consumption and high efficiency.

Lower power consumption due to absence of external heating.

No need to add welding wire, no need to remove oxide film before welding, no need for protective gas when welding friction stir welding aluminum.

Highly automated.

Weldable materials are sensitive to thermal cracks, suitable for welding different materials like friction stir welding of aluminium alloys.

Little maintenance required.

Highly automated. Friction stir processing safety, etc.

- Country: China (Mainland)

- Address: Part Of The West Factory Building, Building 8, No. 2, Yunsheng Technology And Industry Park, Canghai Road ChinaZhejiang

- Contact: Cheeven com