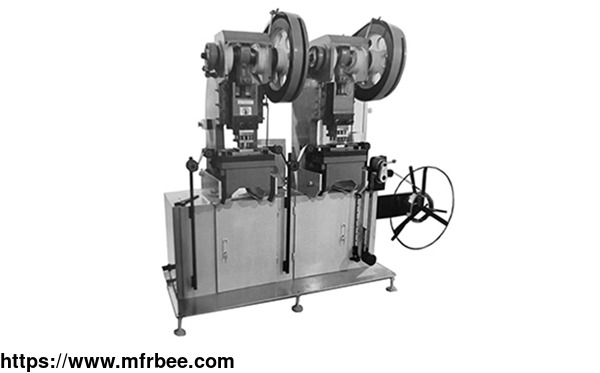

STAINLESS STEEL PUNCHING MACHINE

Product Quick Detail

- FOB Price

- USD $200,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard export packaging

- Delivery

- 30 Days

Specifications

The cnc metal punching machine is punching equipment independently developed and produced by Ningbo Xihe Automation Equipment Co., Ltd. The equipment is to solve the problem of punching the steam

hole of the glass pot cover. With the cooperation of our automatic welding equipment, the steam hole punching of glass pot lids of different sizes can be completed. The equipment has a separate

material rack, feeding device, material storage device and input and output terminals, which more conveniently realize the perfect combination of punching and welding, and realize automatic

production.

STAINLESS STEEL PUNCHING MACHINE PROVIDED BY XIHE

Pot Cover Stainless Steel Punching Machine

HOW DOES STAINLESS STEEL PUNCHING MACHINE WORK?

The stainless steel punching machine is carried out by using two 10T punching machines to form holes on a stainless steel belt. The stainless steel belt is driven by the material rack, the

transmission wheel, the adjustment wheel, and the post-process laser welding machine so that the stainless steel belt passes through the punching at a uniform speed. hole machine. By adjusting the

adjustment wheel and program setting, the punch presses punch the stainless steel strip at the same interval, and the adjustment speed matches the welding speed. The two punches are equipped with

two sets of custom dies so that the hole size and hole spacing of the stainless steel are unified.

DAILY USE AND MAINTENANCE OF STAINLESS STEEL PUNCHING MACHINE

Stainless steel punching machine combined with automatic laser welding equipment will be an ideal choice for automation.

1

After each use of the equipment, power off and shut down, clean the garbage between the workbench and the mold, and check the mold condition.

2

The equipment needs to regularly check the rotation of each transmission wheel, and lubricating oil needs to be added when appropriate. It is recommended to replace the gear oil in the drive wheel

case every three months.

3

The equipment is equipped with punching to die 100,000 times. Before the die reaches the number of times, please replace the die in advance to avoid problems such as burrs on the product.

WORKING CHARACTERISTICS OF STAINLESS STEEL PUNCHING MACHINE

Stability of Stainless Steel Punching Machine

FIRST

Stability

The equipment is equipped with two 10t punches and two sets of punching dies, so as to achieve high-speed and stable punching, and the burr of the product after 100000 times of punching can meet

the requirements of user standards.

Simple Stainless Steel Punching Machine

SECOND

Simple

The equipment is equipped with two sets of adjustment wheels, which can easily and conveniently adjust different product diameters and welding seam positions at any time. At the same time, the

equipment is equipped with material racks, frequency conversion feeding devices, line rail material storage devices, etc., which are simply connected to the welding machine.

We can offer different kinds of metal stamping press for sale and metal punches for sale, if you have needs to buy a custom sheet metal punch, please contact us.

More kinds of laser powered welder, please visit our website.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2019

- Address: No. 28 Jinteng Road, Wuxiang, Yinzhou District, Ningbo

- Contact: ningboxihe com