MANUAL WASTE SORTING ROOM

Specifications

In the manual waste sorting process, all inert and dangerous materials, including metals, glass, electronic trash, PVC, etc., are removed and recycled as raw materials. The flammable waste fuel is

then transferred to buffer storage. During manual sorting of waste, wood, plastics, textiles, and some leftover garbage make up the majority of the waste. Contact waste sorting machine supplier for

manual waste sorting.

Technical Advantages Of Manual Waste Sorting Room

Waste sorting room has an easy-to-maintain simple structure.

Waste can be finely sorted by hand.

Application Of Manual Waste Sorting Room

Material recovery system (MRF)

Mechanical biological treatment (MBT)

Plastic recycling center

Landfill waste sorting plant

RDF Production Facility (Refuse Derived Fuel)

Operating Principle Of Manual Waste Sorting Room

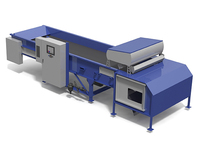

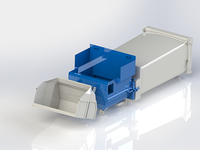

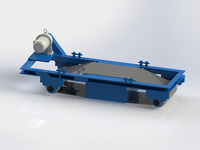

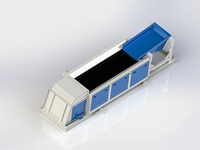

The sorting platform, drop hopper, sorting conveyor, and sorting room are all parts of the manual waste sorting room at Hengchuang. Following preliminary sorting, materials enter the sorting

conveyor, where personnel on either side sift the recyclable garbage before tossing it into the drop hopper, where it enters the bin or conveyor below. A fresh air system that is optionally

installed in the sorting room can enhance the working conditions for sorting personnel.

Q&A Of Manual Waste Sorting Room

What is the Manual Waste Sorting Room?

In home, landfill, and industrial trash sorting operations, manual sorting waste room are a typical sorting studio.

Is the Manual Waste Sorting Room Particularly Smelly?

A fresh air system can be installed inside the enclosed manual sorting room to enhance the working conditions for manual laborers.

If you need any kinds of solid waste management equipment, please contact us, as one of the most professional waste management equipment manufacturers, Hengchuang is willing to offer you high

quality products.

- Country: China (Mainland)

- Founded Year: 253000

- Address: Room 801, office building, No. 1697, Dongfanghong West Road, Xinhu sub district office, Decheng District, DeZhou City, Shandong Province

- Contact: hcmswrecycling com