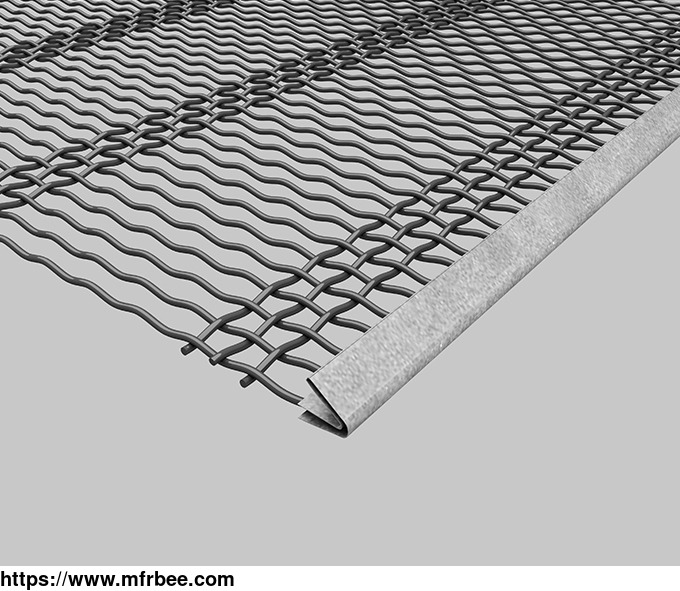

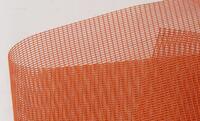

Anpeng Slotted Screen Mesh

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Place Of Origin

- china

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Anpeng woven wire mesh with slotted openings could be woven in any slot length and with any number of wires in clusters. This type of opening provides greater open area, in addition to higher

production compare to regular square mesh. Designed to screen scalp flat, elongated particles, and smaller materials in wet conditions, and also to reduce clogging or blinding of material. Slotted

screens could be customized to have a long aperture with or against the material flow. As one of the professional screen mesh suppliers, our slotted screens are long wearing even against the most

high-impact applications to be found in quarries and mines.

Application of Slotted Mesh Screens

Slotted screen provided by screen mesh suppliers are used in various applications where separating solids and liquids is necessary. Some of the most common applications of slotted mesh screens

include:

Water well drilling:

Slotted screen mesh are commonly used in water well drilling to filter out sand and other small particles from the water.

Mining:

Slotted mesh screens are used in the mining industry to filter out particles from drilling mud and other fluids. The screens are also used to process minerals to remove unwanted particles and

impurities.

Oil and gas industry:

Slotted mesh screens are used in the oil and gas industry to filter out sand and other particles from the drilling fluid.

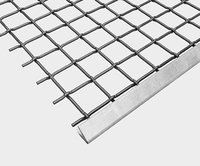

Features of Slotted Screen Mesh

1

Increased open areas than square mesh

2

Less blinding when screening damp material

3

Engineered to increase screening efficiency and reduce blinding

4

Improve effective wear life of screens

5

Wide range of openings and sizes to meet your requirements

6

Ideal when sizing accuracy is secondary to screening capacity

If you need any kinds of industrial screen mesh, please contact us, as a professional woven wire mesh factory, Anpeng is willing to offer you high quality products.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Americas,Europe,Asia

- Founded Year:2001

- Address:No. 12 Weiyi Rd, East Wire Mesh Industrial Zone, Anping County, Hebei, China

- Contact:ap screens