Athermal Packaged FBG

Specifications

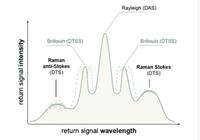

Athermal FBG is a method of compensating the temperature coefficient of fiber grating with a negative temperature coefficient packaging sleeve. It uses a material that does not have a negative

temperature coefficient. The encapsulation sleeve can just fully compensate the wavelength drift caused by the temperature change of the FBG. The encapsulation results in a good temperature

characteristic, in the environment of -5℃ to 70℃, the temperature coefficient of the fiber grating can reach 1pm/℃, and has good long-term temperature characteristic.

Features Of Athermal Fiber Bragg Grating

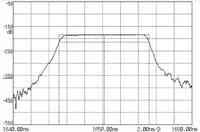

100G/50G Channel Spacing

Low Insertion Loss

Excellent Channel Isolation

Application Of Athermal Packaged Fiber Bragg Grating

Regional and Long Haul

Dwdm Networks

Wavelength Reference

Specification Of Athermal Packaged FBG

Based on FBG technology, FBG optical fiber products are widely used for testing and monitoring safety and health through the variation of particular wavelength of light, passive driving, long time

stability, and sensibility, which can be applied to any harsh environment.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Founded Year: 2010

- Address: 5F, Building B, Chiwan Industry Park, Shaodi Road, Shekou, Nanshan, Shenzhen City

- Contact: at grating