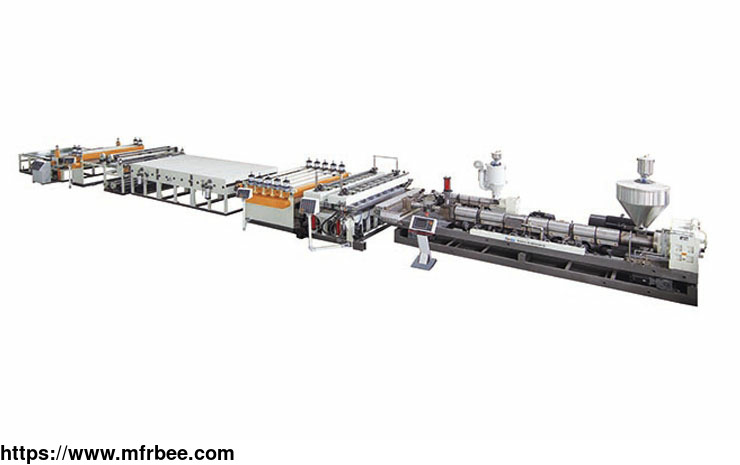

PP Hollow Sheet Extrusion Line

Specifications

Jwell hollow plates are as follows:

PP Hollow Building Formwork Double Out Extrusion Line:

PP hollow building template the first mock exam double production line is the new product launched by jwell company on the basis of traditional 915mm single production line after constant

innovation and constant verification. PP hollow sheet extrusion line meets the requirements of large production and low energy consumption while ensuring the best quality of product.

PC, PP, PE Plastic Hollow Cross Section Plate Extrusion Line:

It is mainly used in the field of packaging and construction, with high production efficiency. PC hollow sheet extrusion line, PP, PE plastic hollow cross section sheet extrusion line can carry out

combined production of different raw materials and recycled materials according to customer requirements, so as to save costs.

PP Honeycomb Board Extrusion Line:

The three-layer sandwich plate which can be formed at one time by extrusion method has a thin surface layer on both sides and a honeycomb structure in the middle; According to the structure of

honeycomb, it can be divided into single-layer plate.

Double plate.

PP Hollow Sheet Extrusion Line Application

Plastic hollow board is an extruded plastic board with PP or PE or PC as the main raw material. Many properties have incomparable advantages of paperboard, wood board, aluminum plate, and other

boards, and can be used as their substitutes in many fields.

PP Hollow Building Formwork Double Out Extrusion Line:

It is used in the construction field to replace the traditional wood board, with a higher recycling rate and can be reused for about 50 times.

PC, PP, PE Plastic Hollow Cross Section Plate Extrusion Line:

Due to its light material, high strength, moisture-proof, good environmental protection performance, and secondary processing performance, PP hollow grid plate can be processed into turnover boxes

and packing boxes. PC sunshine plate from PC roofing extrusion line can be used in the daylighting roof of office buildings, halls, shopping malls, stadiums and public facilities, the canopy of

stations, parking lots, pavilions, lounge corridors, sound insulation barriers of expressways and urban viaducts, etc.

PP Honeycomb Board Extrusion Line:

1. It is applied to the luggage compartment cover, luggage compartment partition, luggage compartment carpet base plate, side wall trim panel, ceiling, and other interior parts of passenger cars;

2. It is used to make all kinds of high-strength packing boxes.

PP Hollow Sheet Extrusion Line Performance and Advantages

Jwell has the following products and advantages in the hollow plate production line:

The improved PP hollow the first mock exam building template production line has:

Three-layer coextrusion production line 2. Three-layer composite distributor 3. Multi-layer lattice mold 4. Three-level setting plate 5. Combined tractor 6. Automatic fixed length cutting machine,

etc. the technology is very mature, there are many successful cases, and the market share in this piece is very high.

There are also PC and PP hollow grid plate production lines:

There are many successful cases in Turkey, Iran, and other countries. PC and PP hollow grid sheet extrusion lines have the advantages of high output, preferential price, simple operation,

convenient maintenance, and so on.

There is also PP honeycomb panel production line:

For the three-layer sandwich plate formed at one time by extrusion method, the equipment processing accuracy of this production line is very high. Jwell has its own parts processing workshop with

mature technology and rich experience. Welcome to visit and investigate at any time!

- Country: China (Mainland)

- Address: No.118 Shangshang Rd.,Liyang City Jiangsu Province,China

- Contact: Mac Sun