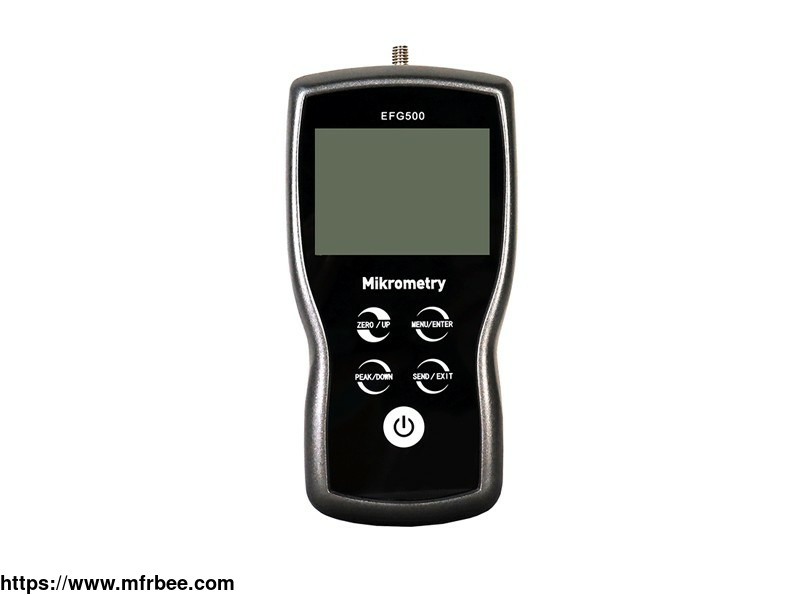

EFG Handheld Digital Compression Force Gauge

Specifications

The digital handheld compression force measurement tool is a small, simple, multi-function, and high-precision push and pull test measurement instrument, which is widely used in electronic

appliances, construction hardware, fire equipment, power machinery, scientific research institutions, and other industries. The digital handheld compression force tester has a high resolution, fast

sampling speed, and is easy to read. And this compression force gauge or sensor is a new high-precision push-pull test instrument.

As one type of handy force gauge, the handheld digital compression force tester has an advanced microprocessor, which can timely access the changes of built-in sensor data, continuous correction of

the zero point, linearity, and temperature drift of the meter, to ensure the high accuracy of the compression measurement instrument over a long period of time. The digital handheld compression

force gauge made by our testing and measuring instruments companies has a compact and reasonable instrument structure, and the digital display is intuitive and clear. The with drawable external

battery can be replaced at will in imported cases.

Handheld Digital Compression Force Gauge Features

Compression Force Meter has a durable metal case

Compression Force Gauges have the automatic reversible display

Handheld Digital Force Gauge equip Touch key for minimized disturbance

Compression Force Gauges take mechanical overload protection

Handheld Force Gauge adopts curve or digital display modes

Compression Force Tester has a calibration certificate

Compression Force Gauges use the charger with US/EUR/UK Plugs selectable

USB or RS232 communication interface, easy to communicate with PLC

Handy Compression Force Tester Specifications

Accuracy ± 0.2% F.S.

Selectable Units N、mN、gf、 kgf、 ozf and lbf

Display 160*128 dot matrix LCD(2.8 inch) with LED Backlight

Overload Capacity 150% of F.S. (LCD blinks beyond 110%)

Overload Protection Overload Protection Mechanism to prevent to be damaged

Measurement Mode Track、Peak、 Auto-Peak、First Peak

Display Mode Curve/digital

Data Sampling Rate 2KHz

Display Update Rate 10 times/second

Memory 1000 data

Set Point Programmable high and low limits

Battery Indicator The display flashes the battery icon when the battery is low

Power 3.6VDC 800mAH Ni-Mh rechargeable batteries

Battery Life Approx. 14 hours per charge

Charger / Adaptor Universal USB/BM charger, Input:110~240VAC

Temperature Effects <0.03% FS per °C

Communication USB or RS-232

Software Free software for USB communication

Outputs RS-232, "Within" set point output, "Under or over" set point output

Operating environment Temperature: -10 to 40°C

Relative Humidity: 20 to 80%

Storage environment Temperature: -20 to +50°C

Relative Humidity: 5 to 90%

Dimensions 160*73*34mm

Weight 0.7 kg (1.5 lb)

Accessories AC adapter/charger, USB cable, 6 attachments: hook, flat tip, conical tip, chisel tip, notched tip, extension shaft

Options Mini-printer, Measuring Adapters, EST-FG1M1 Test Stand, EST-FG2V Motorised Test Stand, EST-FG2H Motorised Test Stand, Ergonomics measuring Kit.

Models Capacity/Resolution

N kgf lbf Ozf gf mN

EFG5 5/0.0005 - 1.1/0.0001 18/0.005 500/0.05 5000/0.5

EFG10 10/0.001 1/0.0001 2.2/0.0005 35/0.01 1000/0.1 10000/1

EFG20 20/0.005 2/0.0005 4.4/0.001 70/0.01 2000/0.5 20000/5

EFG50 50/0.005 5/0.0005 11/0.005 180/0.05 5000/0.5 50000/5

EFG100 100/0.01 10/0.001 22/0.005 350/0.1 10000/1 -

EFG200 200/0.05 20/0.005 44/0.01 700/0.1 20000/5 -

EFG500 500/0.05 50/0.005 110/0.01 1800/0.5 - -

EFG1000 1000/0.1 100/0.001 220/0.05 Jan-00 - -

Handheld Digital Compression Force Tester Technical Drawings

How to Use Digital Compression Force Tester?

1.Choose the model

This series force gauge has a variety of models that can be selected, different models corresponding to different ranges and resolutions, as shown in a table on the back cover of this manual.

Select the appropriate model based on practical need before use. DO NOT exceed the capacity of the gauge, or it may damage the force gauge forever.

2. Choose measuring heads

In order to complete the test work conveniently, the force gauge is equipped with a variety of measuring heads(adapters). Select the appropriate measuring heads according to the actual need.

3. Power on/off

Touch for 2 seconds to power On or Off.

After switching the instrument on, you should check the model whether it is you want.Check Battery Icon. If the power is low, should be recharged.

4. Testing

After completion of the test preparation, testing can be done.

4.1 Measuring heads

Select the appropriate measuring head, and install it in the gauge's measurement axis. Tighten it by hand, without the use of tools. Do not use a deformed or damaged measuring head.

NOTE: Do not use tools to vigorously tighten the measuring head, otherwise it will damage the force gauge.

4.2 Units

The force gauge has a variety of measurement units, select the appropriate unit of force. Under the measure interface, press the Menu key to enter the menu.

4.3 Test Mode

This series force gauge has 3 kinds of measurement test modes that can choose. interface.

You can select a Measure Mode by touching under the measure interface, Or can change it in menus.

Track: The real-time measuring mode, under this mode, press the zero key the force gauge will be cleared (remove tare).

Peak: Peak readings will not change until a higher value is measured. Under this mode, touch the zero key the force gauge will update the display immediately.

Auto-Peak: In this mode, the gauge displays a peak value of force in a fixed duration. The duration time can be set in menus.

4.4 Tolerance Limit

The tolerance limits can be set for GO/NG measurement also.

If you set the alarm on and a valid limit, The icon will be displayed for within limit, lower than lower limit or exceed upper limit.

4.5 Zeroing

Touch clear the force gauge in track mode for removing the tare.

5. Hand-held or Mounting

The force gauge is a portable Instrument, you can do the testing hand-held, or you also can install the force gauge on the test stand so as to obtain accurate measurement results. There are 6 M4.0

mounting screw holes on the back, which can be fixed on the test stand.

NOTE: The depth of the mounting hole is 8.0mm, please choose the appropriate screws, screw into the depth of the force gauge shall not be greater than 7mm.

6. Storage

Measured results can be stored in the force gauge so that you can review or print them later.

Under the measured interface, touch to save value measured, and the save icon be displayed.

7. Browse and Printing

The values saved in memory can be reviewed in the Browse function. The data in memory can be printed into a report.

As a measuring instruments manufacturing company, we can offer sorts of digital push pull force gauge for sale, anything you need, please contact us.

- Country: China (Mainland)

- Founded Year: Shenzhen

- Address: 6th Floor 11# building 3th Section of Yangbei Industrial Park Huangtian Hangcheng Bao'an District, Shenzhen, China

- Contact: mikro metry