Log Accumulators and Automatic Cutting

Specifications

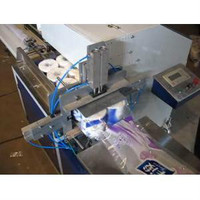

I. Detailed Introduction

1. The machine is used to cut the non-core and roll core toilet paper and kitchen towel logs into short one.

2. The machine has equipped with feeding toilet paper roll log, trimming and rowing waste automatically function.

3. The machine can be connected with packing machine, which can save worker cost to reduce the production cost, and improve production efficiency.

4. The machine has adopted with touch screen, and with counter testing which is easy operate and set.

5. It is very safe when cutting the rolls, and no need workers to operate, which is greatly reduced the past happened in the safety index, and to improve the operating personnel

security and operating efficiency.

6. It can be set the cutting rolls no. on the touch screen.

7. Cutting effect is more nice and neat, not burr, not impartial.

8. The machine is setting advanced, reliable Performance, material parts national standards, and weal well. The mail control parts used imported high quality components, and others

parts is the national standard.

9. It can be ordered 1575 model, 2800model.

II. Main Parameters

1. Machine model: 1571-2800 can be ordered

2. Cutting speed: 60-90 rolls/min (for the ordinary toilet paper roll), 10-20 rolls/min (for the industrial rolls)

3. Cutting roll dia: 90-180mm.

4. Min cutting roll length: 90mm.

5. Power supply: 220V-380V

6. Gas source voltage: 06MPA (offered by customers)

7. Total power: 7.5KW, ( without roll storage is 3KW)

8. Machine size: 3500MM*2500 MM *2000 MM

8. Machine size: 3500MM*2500 MM *2000 MM

- Country: China (Mainland)

- Market: Russia

- Founded Year: 2002

- Address: No.281,Jiahe Road,Siming Area,Xiamen,Fujian,China

- Contact: Tina Chan