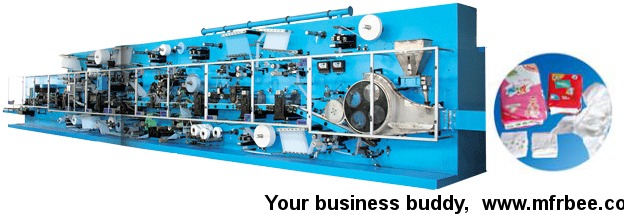

Baby Diaper Machine (DC-BD-550)

Specifications

Function and Features:

1. Crusher System(crush untreated fluff pulp for one time).

2. Fluff pulp feeding device and SAP dispensing device are controlled by

independent frequency inverter.

3. Equipped with cotton core web wheel (or mold wheel) forming and gridding embossing device.

4. Elastic waist, leakage barrier, frontal waist tapes and side waist tapes are available.

5. Main materials unwinding adopts permanent tension control, main shaft driving.

Production processes automatically control, and change material rolls without stopping the machine and decelerating. There is material auto checking device and

can reject defected products.

6. The main material adopts air expanding feeding shaft and automatic edge rectifying device.

7. Frontal waist tapes can use forming material or spreading glue on the machine (the pattern

can be cut as positioned)

8. Bottom film is compounded with PE film and non-woven fabrics.

9. Compact the product after compounding.

10. The machine is automatically controlled by PLC and the whole machine driving is controlled by frequency conversion.

11. There is touch screen on the operating table. Touch screen operation terminal provides man-machine conversation interface, realizing picture digital control (setting of

various parameters, production speed , shift output and trouble display).

12. Products arrangement output device.

13. Safety device is equipped on the operation panel.

14. Stacker is optional according to customer’s requests.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Africa,Middle East

- Founded Year: 2000

- Address: 8-17 Dongpu Road,Siming Area,Xiamen,Fujian,China

- Contact: Amy Zeng