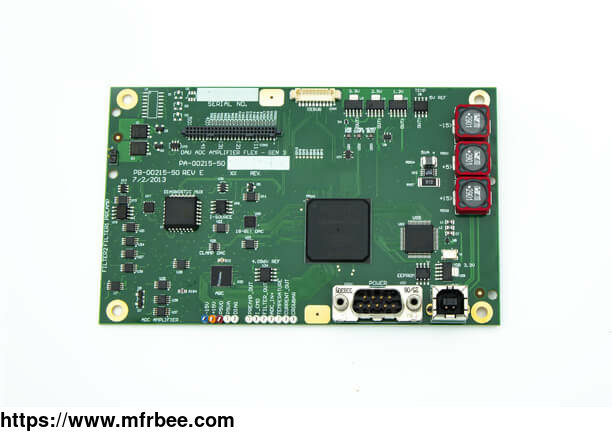

Fastlink Electronics Consignment PCB Assembly

Specifications

If you have a consigned(kitted)job, you can send us bare boards and components(parts). We will do rest assembly using our advanced equipment.

Consignment PCB Assembly is the solution to create a win-win situation for customers and manufacturing suppliers. Because it provides customers with the degree of freedom, flexibility and versatility needed for PCB assembly and prototyping, and enables manufacturers to ensure the fastest turnaround time.

At Fastlink Electronics pcb production and assembly, we specialize in consignment PCB assembly services, which enable our customers to manufacture exclusive parts and remain cost effective. Our commissioned PCB assembly service is customizable, enabling customers to quickly bring their products to market.

By commissioning assembly services, the contract manufacturer will work closely with the customer\'s internal supply chain to assemble the PCB and bring it to market quickly. Once the manufacturer receives the parts needed for the circuit board, they assemble it, helping customers save a lot of time and cost.

Special Features of FastLink\'s Consignment PCB Assembly

Quality Assurance

Customer purchases some or all components. Therefore, the customer can conduct quality control and ensure that the PCB or component is of high quality.

Mass production

If you lack a production setup then this is a great option for you. This is because outsourcing makes it easy to produce on a large scale, thus reducing the cost of purchasing unnecessary equipment.

Reduce turnover times

The quick turn pcb assembly manufacturer Fastlink Electronics offers automated production lines. Turnaround times are often significantly reduced compared to when you produce your own.

Lower manufacturing costs

It allows customers to outsource operations and labor. Besides, no money is needed. As a result, it reduces overall manufacturing costs.

How Does Consignment PCB Assembly Work?

Consignment PCB assembly services have gained tremendous popularity in recent years. If you are looking for PCB consignment services, Fastlink Electronics PCB design and manufacturing offers:

Inventory check so that we can make sure all parts are available before assembly. We redouble our efforts, checking every component to make sure our components are fully ready when the client\'s project arrives.

Store components in our humidity and temperature control cabinet.

warehousing services, customers\' components can be deposited with us for their upcoming projects.

In addition, at Fastlink Electronics, we use automated equipment to perform all assembly processes. We also provide automatic optical inspection, component quality inspection and so on to ensure that your products are of high quality.

For more information about pcb circuit layout, please feel free to contact us!

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2009

- Address: A310, HuaFeng Bussiness Building, Xixiang Rd, Bao'an, ShenZhen

- Contact: fastlink electronics