Fastlink Electronics PCB Box Build Assembly

Specifications

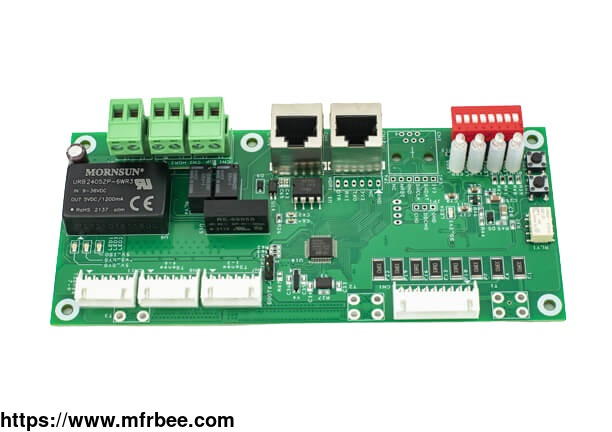

China pcb box build assembly services company Fastlink provides one-stop pcb box build assembly services including Product Assembly, Cable Assembly and System Assembly and various testings for

customer final requirements.

PCB Box Build Assembly services include us assembling various PCBS, connecting them through various cabling and other cables. The process involves making the PCB, installing it, and then connecting

all the components with various wires and cables to get a complete system. This system has many sub-components and many other electronic components installed in the components.

Fastlink Electronics has a professional customer service team, in the face of diverse needs of customers, we are always able to provide perfect solutions, we have rich experience in PCB box

assembly, to meet the needs of customers, let the world redefine the made in China is our mission.

What does the PCB Box Build Assembly Services Include?

At the core of any electronic manufacturing, service comes design, manufacturing, testing, and marketing. The pcb fabrication manufacturer Fastlink Electronics will perform these functions, which

may also include assembling complete systems for OEMs. Designed to provide complete solutions for our customers. In this respect, Fastlink Electronics is trusted by our customers, who always turn

to us for help no matter what their needs are.

For example, by offering fast pcb assembly, systems integration or "box build" services -- Fastlink Electronics can use a process to assemble printed circuit board components, wiring harnesses,

package manufacturing, testing, and more.

PROCESS OF PCB BOX BUILD ASSEMBLY

Step 1

Product Assembly

Step 2

Sub-level Product Assembly

Step 3

System Level Assembly

Step 4

Complete Product Testing including Functional, Environmental, and Burn-In

Step 5

Software Loading

Step 6

Complete System Integration

Step 7

Packaging and Labeling including Barcoding

Step 8

Direct Shipment

There are many pcb fabrication companies, but we are one of the best choices for you.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2009

- Address: A310, HuaFeng Bussiness Building, Xixiang Rd, Bao'an, ShenZhen

- Contact: fastlink electronics