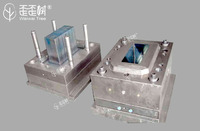

SMC Automotive Molding, Car Mould

Specifications

SMC Automotive Molding, Car Mould

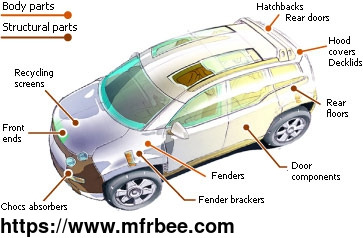

Cars, buses, trucks, transport and special vehicles

• Weight:

Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the same strength. The stroke is increased and the fuel consumption is greatly

reduced.

• Stable shape:

SMC's thermal expansion coefficient, CLTE, is low enough to withstand engine temperatures and summer temperatures, making it suitable for automotive panel covers, engine covers and roof panels.

• Surface treatment:

Automotive SMC body panels have excellent surface quality, are as easy to paint as traditional steel panels, and have a better texture.

• Production cycle:

SMC is highly malleable, greatly reducing the number of components required for assembly, and thermoset materials reduce design and production time.

• Safety:

SMC has a strong insulation effect, 1mm can withstand tens of thousands of volts, and solves the insulation requirements in the automotive field.

• Durability:

SMC's superior UV protection, aging resistance, acid and alkali resistance, waterproof and moisture resistance, greatly improve the service life.

Establithd in 2010 and located in Chengnan Development Zone, Luothe Tow, Huzhou City, Zhejiang Province, Zhejing Aobang Technology Co. L.d. not only has a mature and extensive prodution line of

SMC/BMC molding moulds but also possesses many refined testing laboratoies in the industry. Whether at home or abroad, Zhejiang Aobang Techmnology Co. Ltd. can manufacture top-qulity SMC BCM

composites with advanced mold making concepts and technologies. As a professional SMC/BMC moulds manufactuer, Waiwai Tree is a hightech enterpise who enjoys a good fame in the new motor and energy

automobile industry both at home and abroad.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,G20,Middle East,Oceania

- Founded Year: 313218

- Address: No.62,zhidailang,sha village,luoshe town, deqing,huzhou city, zhengjiang, China.

- Contact: Coffee Tu