Stepper Motor Peristaltic Pump

Specifications

Stepper peristaltic pump motor is the most important part for a full unit peristaltic liquid pump, it is responsible to drive the suitable tubes to reach a specific range of flow volumes with the

help of a stepper motor and driver in the back of the pump head. We offer several models of stepper motor pump to mount in different dimensional systems and achieve different flow rates. Stepper

motor peristaltic pumps are very high cost performance for most fluid transfer systems or production line.

Advantages of Stepper Peristaltic Pump

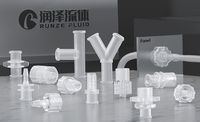

High Quality Materials Selection

RUNZE stepper motor peristaltic pumps are made of engineering plastics like ABS and PC with high strength for industrial use, rollers are made of stainless steels to extend the service life,

peristaltic pump stepper are workable for non-corrosive friendly environment.

High Stability Structure Design

Stepper motor peristaltic pump are equipped with 3 roller, 4 rollers, 6 rollers to meet different flow rate and pulsation requirements, most of them are very easy to open and close to replace

peristaltic tubing, flexible upper blocks are receiving different tube sizes for different flow ranges.

Flexible Application Modes

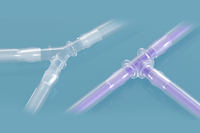

Stepper motor peristaltic pumps are able to be controlled via different types of drivers such as PWM drivers, analog drivers, communication drivers to match with different upper monitors in fluid

system. Tube sizes and fittings options are very flexible to select. They can be used in fluid instruments or bench-top pumps as a good replacement part.

Applications of Stepper Motor Peristaltic Pump

Stepper motor peristaltic pumps are one of the important components in lab, medical and industrial systems, liquid only touch medical grade tubes without any cross contaminations between pumps and

fluids. Stepper motor peristaltic pump is a typical fluid control equipment that widely used in environmental analyzers, laboratory instrument, medical equipment, petrochemical systems, food and

beverage vending machine, bio-pharmaceuticals analysis and metering. High stability is the most important factor, quality materials, high quality molding and machining make these realized.

- Country: Afghanistan

- Business Type: Manufacturer

- Market: Africa

- Address: Room 201 3rd Building Runjing International, No.9 Tianxing West Road, Dongshan Street, Jiangning District, Nanjing

- Contact: runzefluid .com