Ball Screw Nut Assembly

Specifications

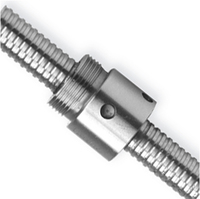

Ball Screw Nut Assembly

The ball screw&nut assembly consists of a screw and a nut, each with matching helical grooves, and balls which roll between these grooves providing the only contact between the nut and the

screw. As the screw or nut rotates, the balls are deflected by the deflector into the ball return system of the nut and they travel through the return system to the opposite end of the ball nut in

a continuous path. The balls then exit from the ball return system into the ball screw and nut thread raceways continuously to recirculate in a ball nut assembly closed circuit.

Types of Ball Screw Nut Assembly

Precision Ball Screw

VXO precision ball screws are ideal for large fabrication machines in injection molding, pressing and metal fabrication. They move heavy loads in horizontal and vertical axes accurately and safely,

while providing long and reliable life with minimum maintenance. Our standard portfolio contains sizes up to 160 millimeters in diameter with a maximum dynamic load of up to 1,440 kN. VXO also has

the capability to customize these ball screw assemblies according to your specific application requirements.

Miniature Ball Screw

Miniature Metric Precision Ball Screws are an efficient and cost-effective solution in a small envelope, ideal for use in small spaces. Ball screw nut assembly range from 4 to 14mm in diameter with

leads from 1 to 20mm - all with standard lead accuracies of ±52µm/300mm. Miniature Rolled Ball Screws are ideal for laboratory, semiconductor, and medical applications.

How Does A Ball Screw Nut Assembly Work?

A ball screw works in a similar way to a conventional linear motion lead screws, but the significant advantage of using a ball screw is that it uses ball bearings running in the helical channel to

transmit the load.

In high precision applications, it is often necessary to translate the rotary motion from a motor to linear motion for the payload. One way of achieving this is by using a precision ball screw and

miniature ball screw.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2011

- Address: 5/F, Bldg. B, Baodai Sci-Tech Park, 988 Wusong Road,Wuzhong Dist, Suzhou, Jiangsu

- Contact: vxolinear motion