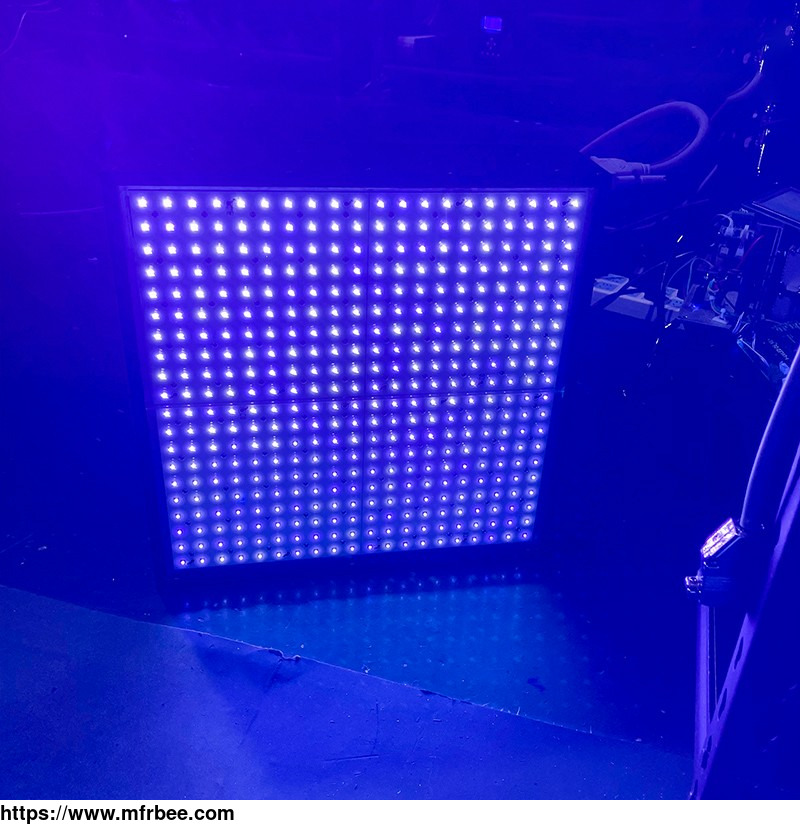

air cooled 365nm LED UV curing LightBar machine

Product Quick Detail

- FOB Price

- USD $2,000.00 / Piece

- Place Of Origin

- china(mainland)

- Minimum Order

- 1

- Packaging

- 1 set each carton

- Delivery

- 7 Days

Specifications

Advantages

1. The UVLED area light source adopts LED chip imported from South Korea; LED lamp beads have the advantages of high energy, strong illumination and long service life;

2. Single-wavelength LED light source is used for irradiation

The conventional wavelength is 365nm, 385nm, 395nm, 405nm, can be customized according to the actual use needs, and the light source has no thermal radiation effect;

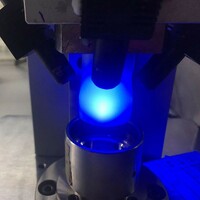

3. UVLED light source has no thermal radiation

Using high-power LED lamp beads, emitting 365/385/395/405nm single-wavelength ultraviolet light source, no infrared wavelength, the surface temperature of the irradiated substrate does not rise by more than 5 °C, no thermal radiation damage to the substrate surface, suitable for drying the surface of heat-sensitive materials;

4. Multi-channel working mode is adopted

Standard equipped with a UVLED light source irradiation head, according to the actual use, choose 1-4 irradiation heads to work separately or synchronously, no need to repeatedly purchase light source equipment, effectively save costs;

5. The machine consumes low power

UVLED light source equipment through the LED chip to convert electric energy ---- light energy, energy loss is small, while the consumption of electricity is low, about one-tenth of the traditional UV mercury lamp, can save a lot of electric energy consumption for enterprises every year;

6. Clean and environmentally friendly, pollution-free

Does not contain "mercury" metal harmful substances, does not produce "ozone" during work, belongs to a clean and environmentally friendly energy;

7. The equipment is small in size

UVLED light source covers an area far less than the traditional UV mercury lamp, can be customized shape size and irradiation area, the average size is about 1/10 of the UV lamp type, light weight, small physical strength, suitable for use in different working environments;

8. Long service life

UVLED emits ultraviolet light source through LED lamp beads, and its use time is more than 20000h, which is much longer than the service life of traditional UV mercury lamps (the average use time is about 800h), and can instantly light up/close the LED ultraviolet light source, not affected by opening and closing.

Applications

1. [Optical communication industry] packaging bonding of active devices and passive devices, curing of surface ink of optical fiber and cable coating;

2. [3C Electronics] mobile phone parts, digital camera accessories, motor components, semiconductor chips, sensors, encoders, etc.;

4. [PCB circuit board] electronic components fixed, core circuit potting, chip protection, antioxidant coating protection;

5. [Medical devices] sealing of medical catheters, syringes, endoscopes, infusion tubes and other medical devices;

6. [Optical parts] assembly and bonding of lens modules, optical lenses and infrared night vision devices;

7. [Laboratory materials] Polymer chemistry, semiconductor materials light curing;

8. [LCD display] low temperature packaging on the surface edge.

- Country:

- Business Type:

- Market:

- Founded Year:

- Address:

- Contact:Lyna Sia

Other products from Futansi (Shanghai) Electronic Technology Co., Ltd.

Relate products of air cooled 365nm LED UV curing LightBar machine

Technical Data Wavelength(±5nm) 365nm / 385nm/395nm/405nm Curing area 300x400mm / custom sizes available Input voltage 220VAC 50Hz / 60HZ Cooling method fan cooling Life >20000 H Conveyor speed 1-10m/min adjustable Belt material Teflon Optic power 1200mw/cm2 (10mm irradiation ...

Technical Data Wavelength(±5nm) 365nm / 385nm/395nm/405nm Curing area 300x400mm / custom sizes available Input voltage 220VAC 50Hz / 60HZ Cooling method fan cooling Life >20000 H Conveyor speed 1-10m/min adjustable Belt material Teflon Optic power 1200mw/cm2 (10mm irradiation ...

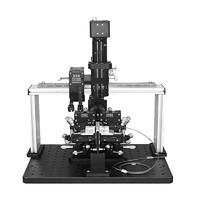

customer specific air cooled high power cool cure 365 spot UV LED curing device Product model: UVSP81 Scope of delivery: Controller + irradiation head (1-4 irradiation heads) + power+ connect cable Product specifications: UV LED spot curing light source (customized available) ...