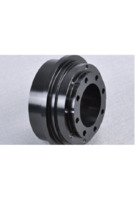

BLACKENING COATING

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Shenzhen

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Put the metal parts into the solution of NaOH, NaNO2 and other potions. At a certain temperature, the parts will react chemically to produce a thin blue (black) oxide film. Blackening can be

divided into normal temperature blackening and high temperature blackening. Generally, the surface oxide film of normal temperature blackening is relatively thin, and the effect of secondary

blackening is better. The blackening surface treatment temperature at high temperature is about 135 ° to 155 ° and the blackening effect is also the best.

What Is Blackening For Metal?

Metal blackening is a common CNC surface finish treatment process. The purpose of blackening is to prevent rust on the metal surface. There are two kinds of metal blackening: alkaline heating

blackening and normal temperature blackening. The problem of checking the antirust effect may occur due to process problems in normal temperature blackening.

How Do You Blacken Metal?

The process flow of metal blackening is as follows:

Degreasing: Boil the parts in degreasing solution for 20~30 minutes at 80~100 ℃.

Cold water cleaning: rinse with flowing clean water.

Pickling: wash with hydrochloric acid solution at room temperature for no more than 30 seconds.

Blackening (put the blackening liquid in a stainless-steel container and heat the bottom with an electric furnace)

Water washing: wash with flowing cold water or warm water for 30-60 seconds.

Boiling water cleaning: 2-5 minutes.

Saponification treatment: temperature 80~90°, time 2-3 minutes.

Immerse in oil: immerse in transformer oil or spindle oil at about 80° for 1-3 minutes, and then the finished product is cleaned.

As a professional cnc machining exporter, Richconn provides cnc machining services, blackening coating, precision cnc machining, etc. Want to know more, contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2003

- Address: 1212, Zehua building, intersection of Longhua Meilong road and donghuanyi Road, Songhe community, Longhua street, Longhua District, Shenzhen,GuangDong,China

- Contact: richconn cnc