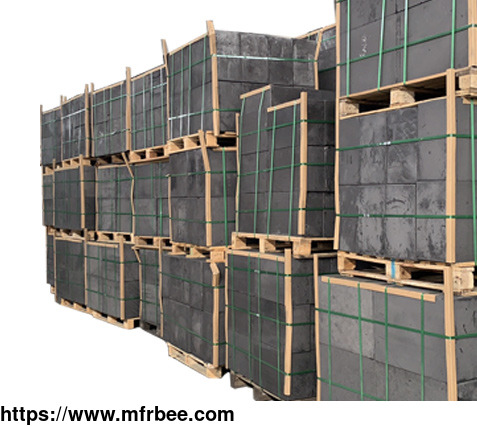

GRAPHITE BLOCKS FOR SALE

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Graphite blocks for sale are generally divided into natural graphite blocks and artificial graphite blocks. The most widely used ones are artificial graphite blocks. As one of the biggest graphite block suppliers/manufacturers in China, WH Graphite can provide you with all kinds ofOEM graphite blocks as you need.

Graphite is an allotroph of carbon, gray black, opaque solid, melting point of 3652℃, boiling point of 4827℃. Solidcarbon graphite block, a stable chemical property, is corrosion resistance, and is hard to react with acid, alkali and other agents. Carbon graphite block burns in oxygen at 687℃ to form carbon dioxide. It can be oxidized by strong oxidants such as concentrated nitric acid and potassium permanganate. The graphite carbon block also can be used as an antiwear agent or lubricant. High purity graphite as a neutron decelerating agent in the atomic reactor, can be used to manufacture graphite crucible, electrode, brush, dry cell, graphite fiber, heat exchanger, cooler, arc furnace, arc lamp, pencil core, and so on.

GRAPHITE BLOCKS FOR SALE

EDM Graphite Block

As China's manufacturing industry is moving towards high-end development, the country is vigorously promoting intelligent manufacturing. Therefore, in the field of precision mold manufacturing, the requirements for the discharge materials used in the processing are becoming higher and higher, so THE position of EDM graphite in the processing of these precision molds is becoming higher and higher, and the screening of EDM materials has been highly concerned by the industry.

Isostatic Graphite Block

Isostatic graphite is made of high purity graphite and has isotropy. Isostatic graphite is a new carbon graphite block developed in the world in the past 50 years, which is closely related to today's high technology. It is irreplaceable for manufacturing single crystal furnaces, graphite crystallizer for metal continuous casting, graphite electrode for EDM, and also an excellent material for decelerating and reflecting materials of rocket nozzles and graphite reactors.

Molded Graphite Block

Molded graphite blocks have a very wide range of properties such as mechanical strength, friction resistance, density, hardness, conductivity and so on, and can be further improved by impregnating resin or metal. Because the molded graphite particle size and internal structure of homogeneity, if not considering the size of the reason he can be used to replace isostatic graphite.

Extruded Graphite Block

Extrudedchina graphite block is a kind of extruded graphite material, mostly used for processing graphite crucible, graphite boat, graphite mold, graphite rotor, graphite heating body, graphite chiller, etc. This kind of graphite carbon block can also be used in strong acid, strong alkali, strong corrosive environment, such as rare earth smelting, chemical industry and so on.

High Purity Graphite Block

High purity graphite block refers to the graphite carbon content >99.99%, the flake crystal integrity, thin and good toughness, excellent physical and chemical properties, with good thermal conductivity, temperature resistance, self-lubrication, conductivity, thermal shock resistance, corrosion resistance, easy to precision machining and other advantages, is the ideal inorganic non-metallic materials.

High Density Graphite Block

OEM carbon graphite blocks are widely used in machinery, casting, and metallurgy industries, with high market benefits. Density is one of the parameters that affect the quality of graphite blocks. High-density graphite blocks have a longer service life, and the density of graphite blocks should be guaranteed above 1.7g/cm³.

Vacuum Furnace Graphite

Graphite carbon blocks with outstanding vacuum, thermal conductivity, and thermal expansion coefficient are small, can be used to make the vacuum furnace heating elements and heat insulation screen, can also be used to manufacture stents, tray, bolts, bearings, fan blades, and other mechanical parts layout, not only cut, such as tungsten, molybdenum, stainless steel metal loss, also use of vacuum furnace is optimized.

Large Graphite Block

Graphite is a carbon crystal mineral element, its crystal lattice is hexagon layer structure, graphite soft, dark gray, has greasy feeling, has several excellent properties, such as high-temperature resistance, conductive, thermal conductivity, therefore has a good application prospect, especially in recent years the rapid development of photovoltaic industry, makes large graphite block material application more widely.

What Are Graphite Blocks Used For?

Carbon graphite block is used in silicon carbide furnaces and other metallurgical furnaces, resistance furnace lining, and conductive material, graphite vacuum furnace as well as permeable graphite heat exchanger.

OEM graphite block is widely used in semiconductor, metallurgy, continuous casting, photovoltaic, EDM, chemical, steel, glass and ceramics, and other fields. The quality of China carbon graphite block is good with stable performance.

PROPERTIES AND CHARACTERISTICS OF GRAPHITE BLOCKS

Good Absorption

Our graphite blocks for sale have good absorption. The void structure of carbon makes carbon has good adsorption, so carbon is often used as adsorption material, used to absorb water, odor, toxic substances, and so on.

ADVANTAGES OF WH GRAPHITE BLOCK

Superior Quality

We understand the importance of quality when it comes to graphite blocks. That's why we source our materials from trusted suppliers and employ stringent quality control measures throughout the manufacturing process. Our graphite blocks for sale are known for the exceptional strength, durability, and thermal conductivity.

Extensive Product Range

Whether you need blocks for molds, electrodes, crucibles, or any other purpose, WH Graphite, the professionalgraphite block factory, has the right solution for you. Our products come in various sizes, grades, and configurations to suit your specific needs.

Customization Options

Our team of experienced professionals will work closely with you to understand your needs and deliver a customized solution that meets your expectations.

Competitive Pricing

We believe that top-quality carbon graphite blocks should be accessible to all businesses. Therefore, we offer competitive graphite block price without compromising on the quality of our products. We strive to provide the best value for your investment, making us a trusted choice among customers looking for cost-effective solutions.

If you want to buy large graphite block, WH graphite is your best chioce.

HOW TO MAKE GRAPHITE BLOCKS?

Our OEM carbon graphite block mainly uses high-quality petroleum coke as raw material, coal asphalt, or synthetic resin as the binder.

Through the preparation of raw materials, ingredients, mixing kneading, pressing, crushing, remixing kneading, molding, many times of roasting, many times of dipping, purification and graphitization, machining, and made of graphite block.

FAQ OF GRAPHITE BLOCKS

Q:

Who is WH Graphite?

Our headquarter is located in Henan, China. Since 2018, our products have been sold to domestic market (60.00%), North America (10.00%), East Asia (9.00%), Africa (8.00%), South Asia (7.00%), Middle East (3.00%) and Western Europe (3.00%).

Q:

How can WH Graphite guarantee the quality of yoursolid graphite blocks?

Each process is produced in strict accordance with the quality standard manual.

Pre-production samples must be available before mass production.

Final inspection is always made before the final shipment of your graphite welding blocks.

Q:

Whatgraphite products can you buy from us?

High Purity Graphite Block, Isostatic Graphite, EDM Graphite, Molded Graphite, Extruded Graphite, Graphite Round, Natural Flake Graphite Powder, Graphite Rod, Graphite Plate, Graphite Crucible, also can be customized according to customer drawings of various graphite moulds.

Q:

Why do you buy graphite products from WH Graphite?

Pingdingshan Wanhui graphite Co., Ltd. is a professionalgraphite products factory, with advanced technology and production equipment, through the ISO9001 quality certification, has an independent R & D team and production lines, can provide professional graphite solutions.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:

- Founded Year:2018

- Address:Industrial Agglomeration Zone of Baofeng County, Pingdingshan City, Henan Province, China

- Contact:whgraphitesupplier com

Other products from Pingdingshan Wanhui Graphite Co., LTD

Relate products of GRAPHITE BLOCKS FOR SALE

In recent years, with the rapid development of die and mould industry, graphite materials, new processes and increasing die and mould factories are constantly impacting the die and mould market. Graphite has gradually become the preferred material for die and mould production ...