Squeeze Casting

Specifications

Aluminum squeeze casting also known as aluminium liquid die forging, is a new metal forming process with casting characteristics and similar to die forging It not only has the advantages of simple casting process, low production cost and complex shape of workpieces, but also has the characteristics of fine grain, uniform structure, good mechanical properties and high forming precision of aluminium die forging products.

What is the mainadvantages of squeeze casting auto parts?

squeeze casting aluminum(Liquid die forging) technology is more and more used in automobile parts.The auto parts produced by liquid die forging not only have excellent product quality, no common problems such as porosity and shrinkage, but also have high blank precision, less machining allowance, high production efficiency and greatly reduced cost. It is an ideal solution for automobile lightweight.

Applications ofsqueeze casting parts for automobile parts

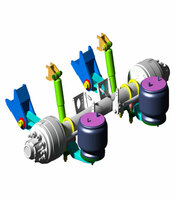

Aluminumsqueeze casting products such as bosch ebike motor mount has obvious advantages to produce automobile parts with complex structure and large bearing capacity byaluminium liquid forging. After years of development, Komman has successfully developed and mass produced many kinds of auto parts, such as truck cab front suspension bracket andair suspension airbag support as the figure below.

If you are looking for a reliableair bag suspension supplier, don't hesitate to contact us!

- Country: China (Mainland)

- Address: 1399 Xindian Road, Jiading District, Shanghai

- Contact: Rick Rick