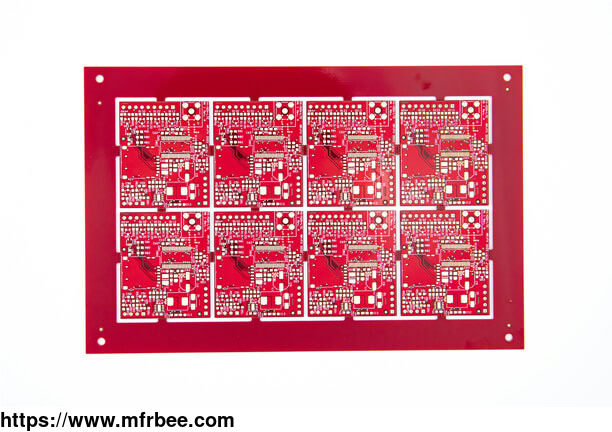

Fastlink Electronics Rogers PCB

Specifications

Most of Rogers 4003 Material, Rogers 4350 Material is available, Rogers 4003 PCB, Rogers RO3003C PCB, Rogers RO4350B PCB, Rogers RO5880 PCB, Rogers RO5870 PCB, etc.

At rogers pcb manufacturer Fastlink Electronics, we combine state of the art technology with our advanced engineering to provide you with the highest quality Rogers printed circuit boards and FR4

printed circuit boards. With over 10 years of experience in providing high quality, on-time, competitively priced products, you can count on us. Our commitment to customer service is reflected in

our willingness to pass rigorous quality control testing of pcb fabrication and assembly, inspect and certify each circuit board prior to shipment in order to provide a 100% defect free China

rogers pcb.

Properties of Rogers PCBs

Rogers PCBs are a type of printed circuit board material made by Rogers Corporation. These PCBs are known for their high performance and reliability, particularly in high-frequency applications.

Some of the key properties of Rogers PCBs include:

Dielectric constant (Dk):

Rogers PCBs have a low and stable dielectric constant, typically ranging from 2.2 to 10.2, depending on the specific grade of material used. A low Dk is beneficial in high-frequency applications,

as it allows for faster signal propagation and reduced signal loss.

Loss tangent (tan δ):

Rogers PCBs have a low and stable loss tangent, typically ranging from 0.0009 to 0.003, depending on the specific grade of material used. A low loss tangent is beneficial in high-frequency

applications, as it indicates lower signal attenuation and reduced signal distortion.

Thermal conductivity:

Rogers PCBs have high thermal conductivity, typically ranging from 0.5 to 2.5 W/mK, depending on the specific grade of material used. This helps to dissipate heat generated by high-power components

and can improve the overall reliability of the PCB.

Tensile strength:

Rogers PCBs have high tensile strength, typically ranging from 90 to 180 MPa, depending on the specific grade of material used. This makes them more resistant to mechanical stress and can improve

the overall durability of the PCB.

Moisture absorption:

Rogers PCBs have low moisture absorption, typically ranging from 0.04% to 0.1%, depending on the specific grade of material used. This helps to prevent the material from swelling or delaminating

when exposed to high humidity or other environmental factors.

In a words, the combination of these properties makes Rogers PCBs an ideal choice for high-performance and high-reliability applications, particularly in the fields of telecommunications,

aerospace, and defense.

Why Choose Rogers Printed Circuit Boards?

There are several reasons why one might choose Rogers printed circuit boards:

High-quality materials: Rogers Corporation is a leading manufacturer of high-performance materials used in a variety of industries, including electronics. Their PCB materials are known for their

high dielectric constant, low loss, and excellent thermal stability, making them ideal for high-frequency applications.

Reliability: Rogers PCBs are known for their reliability and durability. They are designed to withstand harsh environments, such as high temperatures, humidity, and chemical exposure. This makes

them ideal for use in demanding applications, such as aerospace, defense, and medical equipment.

Customizability: Rogers PCBs can be customized to meet specific application requirements. They can be designed to meet specific impedance requirements, thicknesses, and layer counts. This makes

them ideal for use in applications that require precise electrical characteristics.

Industry expertise: Rogers has been in the PCB industry for over 50 years and has a wealth of experience and expertise. They work closely with their customers to provide customized solutions that

meet their unique needs.

Global presence: Rogers has a global presence, with manufacturing facilities and sales offices around the world. This allows them to provide local support and quick turnaround times for their

customers.

Applications of China Rogers PCB

5G Station

Cellular Base Station Antennas and Power Amplifiers

Automotive Radar and Sensors

Microwave point-to-point (P2P) links

LNBs for Direct Broadcast Satellites

Microwave equipment of all kinds.

RF Identification (RFID) Tags

Rogers vs. FR4

Rogers and FR4 are two types of printed circuit board (PCB) materials that are commonly used in the electronics industry. Here are some key differences between Rogers and FR4:

Electrical Properties:

Rogers materials have higher dielectric constants and lower loss tangents than FR4, which makes them better suited for high-frequency applications. Rogers PCBs also have better signal integrity and

less signal loss than FR4.

Thermal Properties:

Rogers materials have better thermal stability than FR4, which makes them better suited for high-temperature applications. Rogers PCBs can withstand higher temperatures without losing their

electrical properties or mechanical strength.

Cost:

Rogers materials are generally more expensive than FR4, due to their higher performance and specialized properties.

Customizability:

Rogers materials can be customized to meet specific application requirements, such as impedance control, thickness, and layer count. FR4 is a more standardized material, with fewer customization

options.

Availability:

FR4 is a widely available material, and many PCB manufacturers have experience working with it. Rogers materials may be less widely available, and it may be more difficult to find PCB manufacturers

with experience working with them.

As a result, Rogers materials are better suited for high-performance applications that require excellent electrical and thermal properties, while FR4 is a more cost-effective and widely used

material for general-purpose applications. The choice between Rogers and FR4 will depend on the specific requirements of the application and the budget constraints.

Benefits of Rogers PCB

01.

High-quality

Rogers PCB's stable temperature and high quality permittivity make it stand out in the industry.

02.

Thermal Expansion

The thermal expansion characteristics of Rogers PCBS are similar to those of copper foils used to strengthen PTFE substrates.

03.

High Frequency and High-speed

Rogers PCBS are ideal for high frequency and high-speed circuits as well as RF products and microwaves.

04.

EMI

Rogers PCBS have low electromagnetic interference (EMI) characteristics, low board resistivity and long-term thermal stability.

Manufacturing and Design Considerations

Manufacturing and design considerations are critical when working with Rogers PCBs. Here are some important factors to keep in mind:

Material selection

Rogers PCBs come in different grades and thicknesses, each with different thermal and electrical properties. Material selection is crucial to ensure that the PCB meets the requirements of the

specific application.

Layer count

Rogers PCBs can be manufactured with multiple layers to handle more complex circuits. The number of layers should be optimized based on the design requirements and the cost of manufacturing.

Trace and space requirements

Rogers PCBs are often used in high-frequency applications where trace and space requirements are critical. The design should take into account signal integrity and ensure that the traces are

properly routed to minimize crosstalk and signal loss.

Vias

Vias are used to connect different layers of the PCB. The type and placement of vias can affect the performance of the circuit. It is important to consider the frequency range of the circuit and

the type of via (e.g., blind, buried, through) to minimize signal loss.

Thermal management

Rogers PCBs have a high thermal conductivity, which can be an advantage in some applications. However, the design should take into account the thermal requirements of the circuit and ensure that

the PCB is properly cooled to prevent overheating.

Manufacturing tolerances

Rogers PCBs have tight manufacturing tolerances, which can affect the yield and cost of production. The design should take into account the manufacturing capabilities of the chosen fabrication

house and ensure that the tolerances are within their capabilities.

Testing and validation

Rogers PCBs are often used in high-reliability applications, and testing and validation are critical to ensure that the PCB meets the required specifications. The design should include provisions

for testing and validation, such as test points or built-in self-test (BIST) circuits.

Final Thoughts

The selection of materials for a printed circuit board (PCB) is a crucial decision that carries significant weight in determining the board's suitability for its intended application. Prior to

engaging a PCB manufacturer for prototyping or production, it is essential to ensure that the material selection has been appropriately considered during the design phase.

The use of Rogers PCB material, in particular, requires careful consideration due to its impact on various aspects of the board's applicability in specific application areas. This material's

selection can have a significant influence on the PCB's overall performance and functionality, making it imperative to make an informed decision.

We trust that the information presented in this article has provided valuable insights into the various aspects of Rogers PCB material, aiding in the decision-making process for designers and

engineers looking to create high-performance PCBs.

Now the rogers ro4350b price is reasonable, if you have needs to buy rogers ro4350b pcb , please contact us.

As a printed circuit design & fab circuits assembly manufacturer, we can offer sorts of pcb fab and assembly for sale, if you are interested, please leave us a message.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2009

- Address: A310, HuaFeng Bussiness Building, Xixiang Rd, Bao'an, ShenZhen

- Contact: fastlink electronics