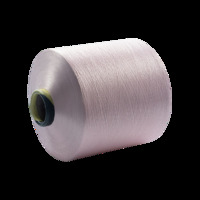

Polyester DTY ZE0006-ZE0668 Silver 121

Specifications

Drawn Textured Yarn (DTY) yarn

Technical Properties of DTY yarn can be moulded in a few ways to make the yarn reasonable for its vast uses. Different heating techniques can be used to make the yarn set for particular use – 1

Heater DTY is normally woolly and more stretchable when contrasted with DTY with 2 Heater. Also the DTY yarn can be made with a several combination of Intermingle points – it can be Non-Intermingle

(NIM) having 0 – 10 knots/meter or Semi-Intermingle (SIM) having 40 – 50 knots/meter or High-Intermingle (HIM) having 100 – 120 knots/meter. These knots are not actually the knots tied when two

threads are broken yet they are the tangle knots created by heating pressure. These Intermingle yarns, also known as Interlaced yarn, are the replacement for lightly twisted yarns. Polyester DTY

yarn can likewise be wound to high winds like 1500 TPM or 4000 TPM (twist per meter). Such twisted yarn can also be heat-set set to make the yarn for all time thermo-set the twist. Catonic DTY is

another variation of Polyester DTY that is mainly used as a part of blankets. Catonic DTY is produced using Catonic PET Chips.

Polyester DTY yarn can also be obtained in different colors by the dope dyed technology or by traditional dyeing. Dope dyed DTY is generally packed on paper bobbins though Raw White DTY that will

be used for dyeing is loosely packed on perforated plastic tube so that all the yarn can be effectively dyed when the bobbin is dipped in color. DTY is mainly produced in huge quantity in China,

India, Taiwan, Indonesia and Malaysia and export around the world.

- Country: China (Mainland)

- Business Type: Hengke Textile Technology Co., Ltd.

- Address: No.188 GongXing Road, QianTang District, Hangzhou, Zhejiang Province, China

- Contact: Hengke Textile