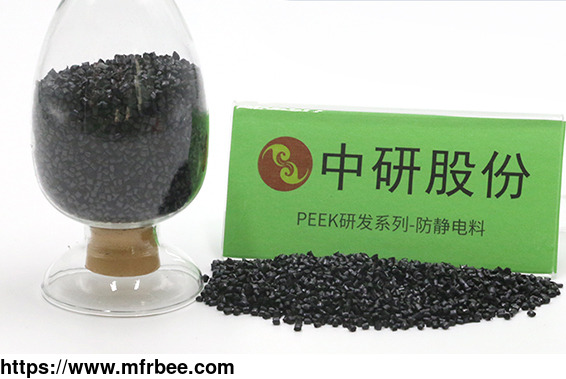

Antistatic Material PEEK R&D Series

Product Quick Detail

- FOB Price

- USD $400.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- carton

- Delivery

- 5 Days

Specifications

Antistatic PEEK R & D Series has excellent electrical insulation, high temperature resistance and wear resistance. Anti-static peek color is black, the biggest feature is excellent electrical

insulation performance.

Specification of Antistatic Material PEEK Polymer R&D Series

Material Properties Test Method Conditions Units 770G

Mechanical Data

Tensile Strength ISO 527 B reak,23℃ MPa -

Y ield,23℃ MPa 100

Tensile Elogation ISO 527 Break,23℃ % 45

Flexural Strength ISO 178 Break,23℃ MPa -

Y ield,23℃ MPa 165

Fleoural Modulus ISO 178 23℃ Gpa 4.1

Compressive Strength ISO 604 23℃ MPa 125

Charpy Impact Strength ISO 179/leA Notched kJm-2 7

ISO 179/IU Unnotched kJm-2 -

Izod Impact Strength ISO 180/A Notched kJm-2 7.5

ISO 180/U Unnotched kJm-2 -

Mould Shrinkage ISO 294-4 Along flow % 1

Across flow % 1.3

Thermal Data

Melting Point ISO 11357 ℃ 343

Glass Tansition (Tg) ISO 11357 Onset ℃ 143

Special Heat Capacity DSC 23℃ kj kg-1℃-1 2.2

Coefficient of Thermal Expansion ISO 11359 Along flow below Tg ppm K-1 45

Along flow above Tg ppm K-1 120

Heat Deflecion Temperature ISO 75A-f 1.8Mpa ℃ 152

Thermal Conductivity ASTM C177 23℃ W m-1K-1 0.29

Flow

MeltIndex ISO 1133 380℃,5kg g10min-1 10

Miscellaneous

Density ISO 1186 Crystalline gcm-3 1.3

Amorphous gcm-3 1.26

Shore D Hardness ISO 868 23℃ 85

Water Absorption(3.2mm thick Tensile Bar) ISO 62-1 24h,23℃ % 0.07

by immersion Equilib riu m,23℃ % 0.4

Electrical Data

Dielectric Strength IEC 60243-1 2mm kV mm-1 23

Comparative Tracking Index IEC 60112 V 150

Dielectric Constant IEC 60250 23℃,1kHz 3.1

23℃,50kHz 3

Loss Tangent IEC 60250 23℃,1MHz 0.004

Volume Resistivity IEC 60093 23℃,1V Ω cm 10 16

275℃ Ω cm 10 9

As one of peek material manufacturers, we can offer sorts of related products for sale, if you have needs, please contact us.

- Country: Afghanistan

- Address: No.1177, Zhongyan Road,Luyuan Economic Development Zone,Changchun, Jilin,Province ,China 130113

- Contact: miss shen