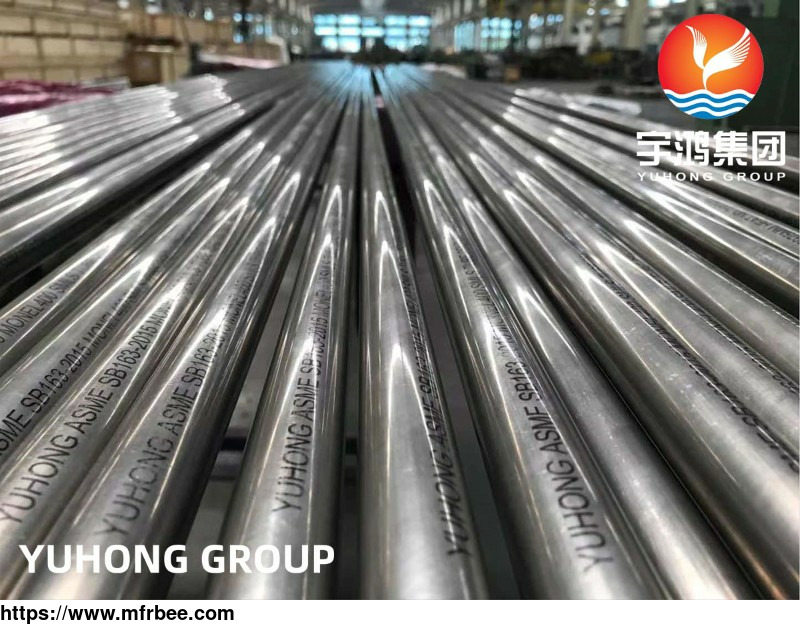

ASTM B163/ASME SB163 NICKEL ALLOY PIPE/TUBE

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Ningbo, China

- Packaging

- Wooden case, woven bag in bundle

- Delivery

- 10-15days

Specifications

ASTM B163 is the Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-exchanger Tubes. This covers outside diameter and average wall, or outside diameter and minimum wall tube. The

tube shall be furnished in the alloys and conditions defined by this specification.

The ASTM B163/ASME SB163 material shall conform to the composition limits of nickel, copper, molybdenum, iron, manganese, carbon, silicon, chromium, aluminum, titanium, phosphorus, cerium, and

zirconium, yttrium, boron, cobalt, columbium, tungsten, and nitrogen specified. Tensile strength, yield strength, elongation, and Rockwell hardness of the material shall conform to the required

Mechanical Properties set by this specification.

Test methods such as chemical analysis, tension, rounding procedure, Rockwell hardness, grain size, and hardness conversion shall be performed for qualified ASTM B163/ASME SB163 alloy tubes.

ASTM B163/ASME SB163 NICKEL ALLOY PIPE/TUBE PROVIDED BY YUHONG

ASTM B163/ASME SB163 Nickel Alloy Pipe/Tube

The most popular materials under ASTM B163 Standard are: UNS N04400(Monel 400); UNS N06600(Inconel 600); UNS N08800(Inconel 800); UNS N08810(Incoloy 800H); UNS N08811(Incoloy 800HT); UNS

N08825(Incoloy 825).

Incoloy 800/N08800 Nickel Alloy Pipe/Tube

Incoloy 800H/N08810 Nickel Alloy Pipe/Tube

Incoloy 800HT/N08811 Nickel Alloy Pipe/Tube

Incoloy 825/N08825 Nickel Alloy Pipe/Tube

Inconel 600/ N06600 Nickel Alloy Pipe/Tube

Inconel 601/ N06601 Nickel Alloy Pipe/Tube

Monel 400/N04400 Nickel Alloy Pipe/Tube

Nickel 200/N02200 Nickel Seamless Pipe/Tube

ASTM B163/ASME SB163 NICKEL ALLOY PIPE/TUBE FEATURES

Nickel alloys tube under ASTM B163 can meet the High Strength and corrosion resistance in a range of media including sea water, hydrofluoric acid, sulphuric acid, and alkalies.

ASTM A163 Coiled Tubing is highly resistant to corrosion in different environments. This tubing enables the speed of the operation to be fast at the same time, it is very safe and easy to run. ASTM

B 163 Tubing is used in applications for drilling, logging, fracturing, perforating, and production operations. These tubings have a lower environmental impact.

As a ss tube manufacturer, we can offer sorts of related products for sale, if you have needs, please contact us.

- Country: Afghanistan

- Business Type: Manufacturer

- Market: Oceania

- Address: Room 1005--1007, No.1 New World Building, NO.1018 Min'an Road, Yinzhou District, Ningbo, China

- Contact: YUHONG .com