Tapered Roller Bearings

Specifications

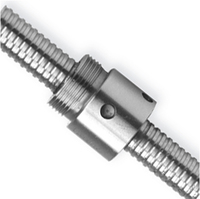

Tapered roller bearing, which is produced by VXO cam roller bearings, a tapered roller bearing supplier, have tapered inner and outer ring raceways and are configured with tapered rolling elements.

This design can withstand the simultaneous action of combined axial and radial loads. The followings are the dual tapered roller bearings for sale.

Key Features of Tapered Roller Bearing

Low friction - The roller end face and the baffle are optimally designed, and the baffle guide surface is polished to reduce its roughness, thus promoting the formation of lubricating oil film and

reducing friction. It also reduces the wear of the retaining edge. Preload is better maintained and noise levels during operation are reduced.

Long service life - Optimized design of the outer surface profile of the rolling element with convexity or logarithmic curve shape can optimize the load distribution between the contact surface of

the raceway surface and the rolling element, avoiding the generation of edge stress at both ends of the rolling element. And it can reduce the sensitivity of the bearing to misalignment error and

shaft deflection.

Improve bearing reliability - THB flange mounted tapered roller bearings raceway and rolling body surface profile are optimized and finely machined to ensure a lower surface roughness. It is more

conducive to the formation of lubricating oil film when working. Thus improving the overall performance and reliability of the bearing.

Tapered Roller Bearing Types

Tapered roller bearings are separable bearings. Both the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four harga

tapered roller bearing according to the number of columns of rolling elements.

Generally, the tapered angle of the outer ring raceway of a single row tapered roller bearing is between 10° and 19°, which can bear the combined action of axial load and radial load at the same

time. The greater the cone angle, the greater the ability to withstand axial load. Bearings with large taper angle, add B to the rear code, and the taper angle which is between 25° and 29°can bear

larger axial loads. In addition, single row tapered roller bearings can adjust the size of the clearance during the installation process.

The cup (or cone) of a high speed tapered roller bearings is a whole unit, integrated. The small end faces of the two cones (or cups) are opposite, with a spacer in the middle. The clearance is

adjusted by the thickness of the spacer. The thickness of the spacer can also be used to adjust the preload of the double row tapered roller bearing.

Accuracy: Generally, the accuracy of single-row and double-row cylindrical roller bearings is better than that of single row tapered roller bearings. Compared with other types of bearings,

cylindrical roller bearings and tapered roller bearings have lower accuracy.

Noise: Among them, the single row cylindrical roller bearing has the lowest noise.

These differences determine their different working environments. If you want to choose the most suitable bearing, you need to know enough about the characteristics of the bearings.

The N type and NU type can move axially, can adapt to the chan

For more information about linear motion control systems and linear guides and bearings, please feel free to contact us!

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2011

- Address: 5/F, Bldg. B, Baodai Sci-Tech Park, 988 Wusong Road,Wuzhong Dist, Suzhou, Jiangsu

- Contact: vxolinear motion