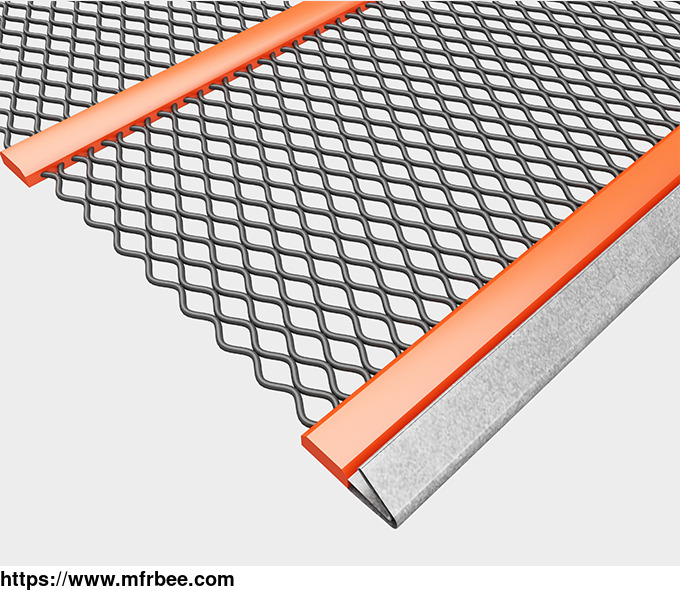

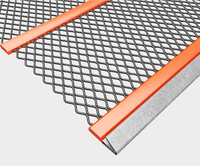

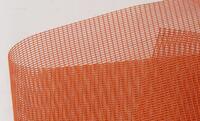

Diamond Opening Self-cleaning Screen

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15-21 Days

Specifications

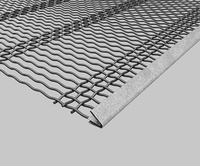

Anpeng Diamond shape self-cleaning is consist of crimped round wires bond togther by polyurethane bars creating the 'Square' or 'Diamond' openings. This type of screens serves all the functions

of traditional Square woven wire mesh, by providing precise sizing control and increase open area. What's more is that the diamond screen mesh is able to eliminate blinding, pegging and clogging

problems due to its special design and structure. Each wire will vibrate at different frequency during screening, and this is what creates the self-cleaning effects of all our self-cleaning series.

Features of diamond mesh screen

1

Eliminate blinding and clogging

2

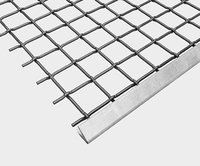

Higher open area than traditional square mesh

3

Increase production and lower costs

4

Accurate sizing

5

Wear resistance, corrosion resistance

6

High screening efficiency – up to 40 % more throughput

Self-cleaning Screens Quality Control

Anpeng Self-cleaning screen Quality Control

Incoming Goods Inspection (IQC)

Raw materials such as high tensile steel wires, polyurethane, and stainless steel wires underwent rigid inspection by our QC inspector when first arrive at our warehouse. We test the chemical

components, physical properties, and general conditions of the materials. Defective goods would be returned or disposed of, which would not be used in any Anpeng Wire Mesh Production Process.

As a professional wire mesh screen factory, we provide quarry mesh, vibrating screen cloth, industrial wire mesh and etc. For more information, please feel free to contact us!

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Americas,Europe,Asia

- Founded Year:2001

- Address:No. 12 Weiyi Rd, East Wire Mesh Industrial Zone, Anping County, Hebei, China

- Contact:ap screens

Other products from Anpeng Wire Mesh Filter Equipment Co., LTD

Relate products of Diamond Opening Self-cleaning Screen

7 Inch HDMI Touch Screen Display 1024x600 TN+Ofilm 40PIN HDMI+USB IPS 450nits Open Frame LCD

This 7 Inch HDMI Touch Screen Display is suitable for use in MB products .The open frame display lcd tft adopts one backlight with High brightness 27-lamps white LED.Construction: 7.0 〞a-Si color TFT-LCD ,White LED backlight, FPC. General Specifications of 7 Inch HDMI Touch ...