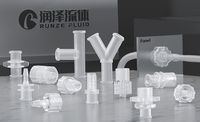

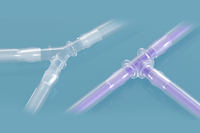

Flangeless Fittings

Specifications

Flangeless Fittings benefits a lot for low pressure and gastight removable systems which comes with a nut and a ferrule as a unit set to connect rigid tubing of outer diameter

1.6/2.0/2.5/3.0/3.175/3.2mm into a same thread receiving port, it is very convenient to use by hand tightened without any tools and easy to mounting into fluid systems.

Specification of Flangeless Fittings

Model No. Flangeless Nut Ferrule Size Tubing OD (mm)

B-611 WF10A YE-020 / YE-016 2.0

1.6(1/16")

B-612 WF03G YE-020 / YE-016

B-613 WF08BL YE-020 / YE-016

B-614 WF08B YE-020 / YE-016

B-615 WF05EL YE-020 / YE-016

B-616 WF05E YE-020 / YE-016

B-617 WF06CL YE-020 / YE-016

B-618 WF06C YE-020 / YE-016

Model No. Flangeless Nut Ferrule Size Tubing OD (mm)

B-619 WD10A YC-032 / YC-030 / YC-025 3.2 (1/8")

3.0

2.5

B-620 WD03G YC-032 / YC-030 / YC-025

B-621 WD08BL YC-032 / YC-030 / YC-025

B-622 WD08B YC-032 / YC-030 / YC-025

B-623 WD05EL YC-032 / YC-030 / YC-025

B-624 WD05E YC-032 / YC-030 / YC-025

B-625 WD06CL YC-032 / YC-030 / YC-025

B-626 WD06C YC-032 / YC-030 / YC-025

Dimension (unit: mm)

Application Note of Flangeless Fittings

1. Choose 1/4-28 nut when receiving port is 1/4-28; Choose M6 nut when receiving port is M6.

2. Before connecting fittings, ensure the end of the tubing has a clean, square, burr-free cut. This is very important, as the square cut helps the tubing make full contact with the bottom of the

mating port. Neglecting to properly cut the tubing could lead to dead volume, resulting in peak distortion such as fronting, tailing or broadening.

3. Two-Piece Fittings Installation Steps:

a. Slide the nut, followed by the ferrule, at least 3/16” (4.7625mm) from the end of the clean cut tubing

b. Insert the assembly into the receiving port, pushing the tubing into the port until it bottoms out.

c. Finger tighten the nut into the port until snug.

d. After several uses (especially at high pressure) the ferrule should be replaced.

Nanjing Runze Fluid Control Equipment Co., Ltd. founded in 2014, was born a high-tech manufacturer engaged in R&D, production, marketing, and service for microfluidic components including

peristaltic pump, syringe pump, piston pump, multiport valve, tubing, plastic fittings, which are key parts in environmental analysis, laboratory, medical device, bio-pharmaceuticals, petrochemical

engineering, food, and beverage. Based on stable development and constant pursue of high-level cooperation on safety, quality, reliability, and innovation, RUNZE FLUID has obtained I S O 9 0 0 1

certification, 32 invention patents, and CE RoHS FDA certificates to enhance our service capabilities.

- Country: Afghanistan

- Business Type: Manufacturer

- Market: Africa

- Address: Room 201 3rd Building Runjing International, No.9 Tianxing West Road, Dongshan Street, Jiangning District, Nanjing

- Contact: runzefluid .com