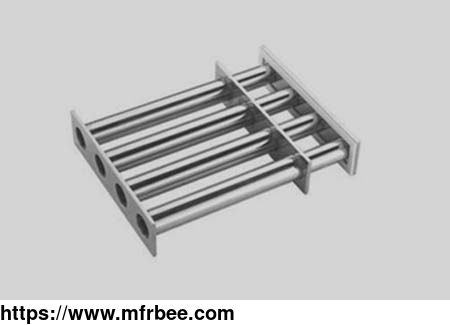

Magnetic Grate Separators/Magnetic Grid Separators

Specifications

Magnetic grate also is known as the magnetic shelf, magnetic frame, magnetic stand and magnetic hopper grate.

Magnetic grate separators are assembled by several or more super powerful magnetic bars.Each bar from the magnetic grate has the extreme strong force. The magnetic grate separators are used to separator the tiny impurity from the powder material, liquid material or gas. They usually fixed at the feeder nose, outlet and running pipes. When the material flow through the magnetic grates, the metal impurity are all absorbed onto the magnetic grates. So that the magnetic grates can extremely improve the purity of the material, and also lengthen the working life of the material treatment equipment.

Magnetic grates are composed of magnetic bars and the steel plate that used to fix the magnetic bars. Magnetic bars can be fixed by different arrange, and magnetic grate separators can be made into various shapes, square shape, round shape, triangle, oval shape and irregular shapes. The center distance of the magnetic bars is usual 2 inches, all frame and housing.

The features of magnetic grate/grid separators

1. Extreme strong magnetic force, the surface magnetic field power can be up to 12000Gs for the magnetic bars with the diameter of 25mm.

2. The surface of the magnetic bars are sealed and welded by stainless steel-304, stainless steel-316 or stainless steel-316L, and with polishing treatment, it can be used to treatment powder or liquid material.

3. With polishing treatment on the surface, the magnetic bars is meet the requirement of food safety grade.

4. The diameter and length of the powerful magnetic bars can be made according to customer’s need, the common diameter of the magnetic bar is 25mm(1”), the maximum length for the magnetic bar can be made up to 2500mm for the diameter 25mm.

5. The strong magnetic bars are usually made as round shape, square shaped magnetic bars also be made out.

6. The maximum working temperature of the normal magnetic bars is 80℃, it can also be made for more higher working temperature according to clients need.

7. Various designs, standard type, easy clean type, single layer, multilayer type, hooks and handles can be made.

Application fields:

Because of the simple structure and variety of design of the magnetic grates, compared with other whole sets of separate equipment, it is easy to operate and install. And because of the low requirement of install conditions, it is more widely used, it suits for the production line of food, medicine, chemical, plastic industry.

This information needed when you order the magnetic grate

1. the dimension of the magnetic grate

2. the shapes of the magnetic grate

3. the layer quantity of the magnetic grate

4. the maximum working temperature of the magnetic grate

5. the requirement for the magnetic field for the magnetic grate

6. all other special requirements about the magnetic grate

Meank, as an excellentholding magnets manufacturer, offers a wide range ofstrong magnets for magnet fishing for you to choose from.

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Europe,Americas

- Founded Year: 2013

- Address: 1FLOOR,NO.128 BUILDING-1 128#, JIJIN ROAD,XIAOGANG,BEILUN,NINGBO

- Contact: meankmagnet meankmagne