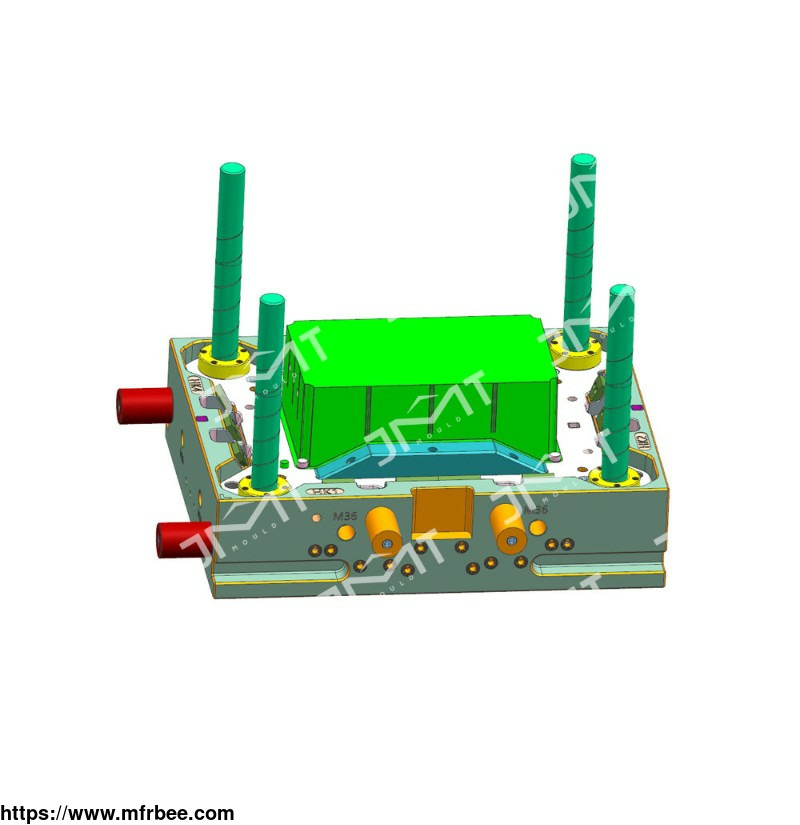

Plastic toys container mould

Specifications

In the dynamic world of toy manufacturing, precision and innovation are keys to creating safe, functional, and delightful products. ThePlastic Toys Container Mouldplays a central role in shaping these toys\' storage solutions, ensuring both quality and functionality. This article delves into the details of the Plastic Toys Container Mould, highlighting its significance and the craftsmanship that goes into its creation.

1. Overview of Plastic Toys Container Mould

The Plastic Toys Container Mould is an indispensable tool used to craft containers designed to store and protect children\'s toys. These containers come in various shapes and sizes, often featuring vibrant colours and playful designs. The mould\'s quality and precision are vital to producing storage solutions that are not only attractive but also functional and safe.

2. Materials and Manufacturing Process

Creating a Plastic Toys Container Mould begins with the careful selection of materials. High-quality steel, aluminium, or other durable materials are commonly used to ensure the mould\'s longevity and precision. The choice of material depends on the specific requirements and preferences of the manufacturer.

The manufacturing process itself is a meticulous operation that often utilizes CNC (Computer Numerical Control) machining. This advanced technology enables the creation of intricate designs with precise dimensions. Skilled engineers and machinists work together to ensure that every aspect of the mould is accurately reproduced, down to the smallest details.

3. Design Precision

The design of the Plastic Toys Container Mould is pivotal in achieving consistently high-quality results. Engineers and designers employ state-of-the-art CAD (Computer-Aided Design) software to create a 3D model of the mould. This 3D model serves as the blueprint for the mould\'s construction.

Precision in design extends to every aspect of the mould, from the overall dimensions to the fine details that give toys\' containers their unique character. The mould\'s ability to produce identical plastic containers repeatedly depends on the accuracy of the design.

- Country: China (Mainland)

- Business Type: Zhejiang Huaqi Information Technology Co., LTD

- Market: 美洲,欧洲,欧洲联盟

- Founded Year: 2002

- Address: No.188, Hequ Road, Chengjiang, Huangyan, Taizhou, Zhejiang, China

- Contact: JMT Commodity Mould Co., Ltd.