Reflex Level Gauge

Specifications

REFLEX LEVEL GAUGE WITH LEVEL GAUGE GLASS

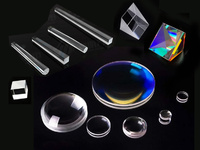

Reflex Level Gauge is a sophisticated device used to measure liquid levels in a container. It utilizes a reflex glass with a prismatically grooved face pointing towards the gauge chamber. This setup facilitates a clear distinction between liquid and gas/vapor zones based on their brightness, resulting in an efficient and easy-to-read level indication.

Reflex Level Gauge with Level Gauge Glass

Reflex glass level gauges

Materials:

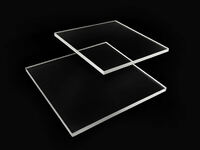

Level gauge glass. The critical component of a reflex level gauge is its level gauge glass. This glass is engineered to withstand the harsh conditions of various industrial applications, exhibiting resilience even under high pressure, high temperatures, or corrosive environments. It can be easily sourced and installed, thanks to the convenience of online shopping.

Level Gauge Working Principle:

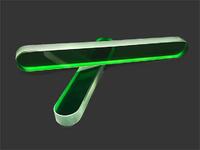

The Reflex Glass Level Gauges operate based on light refraction and reflection principles. These gauges utilize specially crafted glass angled towards a chamber with 90° prismatic grooves. During usage, liquid fills the lower chamber section, while gases or vapors occupy the upper part. The liquid level is discerned from the distinct brightness contrast between the zones. Reflex gauges function efficiently without specific illumination, relying on natural daylight, and only need artificial lighting at night. The variation in brightness is achieved as follows:

The liquid zone appears significantly dark during operation due to the refraction of most light rays inside the liquid, resulting in an almost black appearance because the non-reflective gauge chamber interior prevents the refracted rays from being externally visible.

In contrast, the gas/vapor zone appears nearly silver due to total reflection of light rays at the glass/gas-vapor interface. This reflection, causing a 90° turn, makes the rays observable, thus giving the zone a bright silver appearance.

Level Gauge Applications

Reflex glass level gauges are versatile, finding use in numerous applications, except when reading the separation level between two liquids (interface), observing the liquid color, protecting the glass from high-pressure water steam or corrosive substances. In these cases, additional shields are required.

Reflex level gauges are unsuitable in specific scenarios, such as:

Reading the separation level between two liquids (interface).

Instances requiring both level indication and observation of the liquid color.

Situations involving high-pressure water steam, where the gauge glass must be protected from boiler water’s solvent action using mica shields.

Reflex Level Gauge with Level Gauge Glass Advantages

The Reflex Level Gauge offers several benefits, including low initial and operating costs and easy level readings. It provides a robust solution to liquid level measurement even in challenging environments, ensuring dependable performance and longevity.

Depending on your specific needs, various configurations, functionalities, and price points are available. Whether it’s for a new equipment assembly, repair, or simply enhancing equipment readability and usability, reflex level gauges prove to be a valuable addition to your process control toolkit.

- Country: China (Mainland)

- Business Type: Hebei Hengshui Aohong Technology Co.,Ltd

- Market: 非洲,美洲,亚洲,新兴市场,欧洲,欧盟,G20,中东,大洋洲

- Founded Year: 2008

- Address: 161# Ronghua Street, Taocheng District, Hengshui, Hebei, China

- Contact: Feng Wang