CERAMIC GRAINS

Product Quick Detail

- FOB Price

- USD $3.00 / Piece

- Minimum Order

- 200000

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 45 days

Specifications

The alumina abrasive having a microcrystalline structure obtained by the gel method is called ceramic abrasive grain. Through special processing, each grain has thousands of tiny crystals. This

structure brings very good self-sharpness performance of the grains, which can continuously reveal new and sharp cutting edges.

RIKEN RMC wood grain ceramic is very dense, rough, strong and sharp. When worn, the ceramic abrasive grain will produce a sharp cutting edge similar to the knife edge. Therefore, the ceramic

abrasive grain will have a lower cutting temperature and lower burnt than the ordinary alumina when sanding hard to sand materials. It can be keeping sharpness for a long time with low loading. So

that will bring you less total downtime and longer life.

Brief Introduction of Ceramic Abrasive Grain

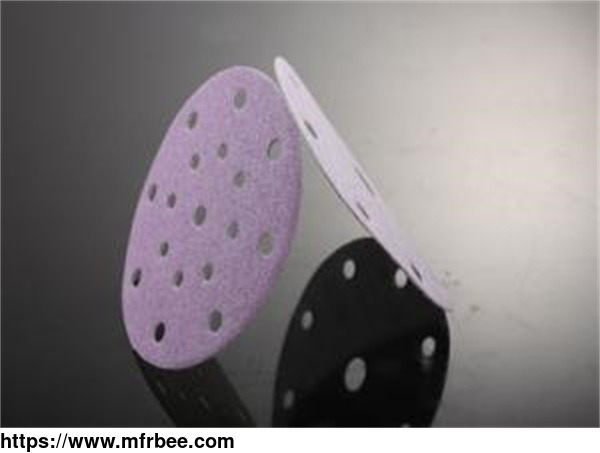

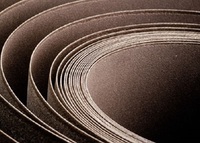

Wood grain ceramic products could process into kinds of shapes, like belts, sand discs, sheets. The grains character decide that products have longer sanding life, higher cutting force and higher

sanding efficiency performance.

Ceramic abrasive belts and sanding discs could bring you rapid cutting on difficult-to-sand materials such as aerospace, aerospace alloys and forged steel. The unique ability of ceramic abrasives

increase production and reduces labor costs. Riken abrasives RMC wood grain ceramic products also have a good performance in general sanding in auto repair, steamships, and aluminum alloys.

The ceramic abrasive grain is a new abrasive with a microcrystalline structure prepared by gel sintering. It does not use the smelting method and uses Al2O3 below 5 microns. In the presence of an

acid, some of the oxides is added to produce gelatin, which is made into granules. The raw material is strict, and the content of sodium oxide is less than 5%. It is characterized by non-smelting

and crystallization within 3 microns.

Ceramic abrasives are hard and tough. Fine crystal shape can make Abrasives fall off regularly at different levels, make self-sharpening orderly, keep the sharpness of the whole abrasive, and have

good processing effect.

Working conditions are equally important. Temperature and pressure are more important. Crystals are destroyed one by one to achieve self-sharpening.

It is first used to coat abrasives, which is 3-5 times higher than ordinary corundum (ordinary 100, zirconium corundum 207, ceramic abrasive 333).

At present, the world-famous ceramic abrasives factory include Saint-Gobain, 3M, Tebuck , VSM and Hermes. American 3M company is called "Cubitron", and its maximum crystallization is less than 3

micron.

Norton company is called SG abrasive, its crystal form is several microns; German Hermes company is called CB abrasive, its maximum crystallization is less than 5 microns. The crystal type of CX

abrasive in Japan is called 1 micron, but in fact, it is less than 3 micron.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,Middle East,Oceania

- Founded Year: 2002

- Address: No.8, North Road, New & High Industrial Zone, Zibo, Shandong,

- Contact: Guizhen Zhu