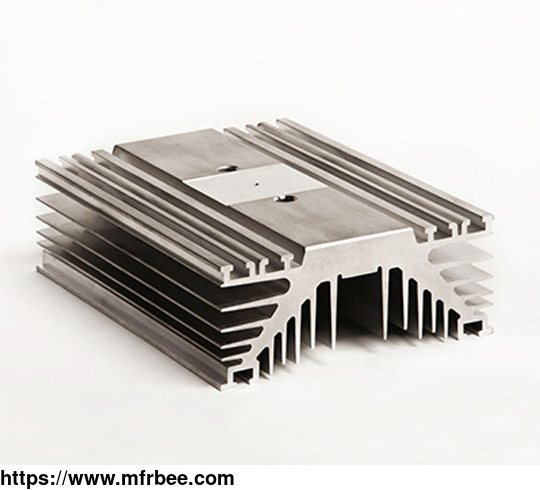

Aluminium Heatsink Profile

Specifications

An extruded aluminum profile heatsink is a cooling device made of aluminum that is produced using an extrusion manufacturing process. The process involves pushing or pulling a block of aluminum

through a die to create a specific shape or profile. The aluminum is then cut to the desired length and machined to form fins, holes, or other features that can enhance its cooling performance.

Otalum, one of the leading aluminum heatsink extrusion profiles factory in China, stocks a wide range of aluminum extrusion heat sink profiles and provide aluminium extrusion heat sink profiles to

custom designs, available in a range of finishes. If the existing products are not suitable for your needs, our technical team can help you to design your products and realize them.

All extrusions can be supplied as cut, drilled, or machined to customer specifications. As a professional extruded aluminum heatsink manufacturer, Otalum operates the latest CNC drilling and

machining centres which provide accurately machined, cost-efficient parts on short cycle-times.

What is a heat sink?

A aluminium heat sink bar is a component that increases the heat flow away from a hot device. It accomplishes this task by increasing the device's working surface area and the amount of

low-temperature fluid that moves across its enlarged surface area.

Why Aluminium Heat sink?

An extruded aluminum heat sink profiles is the most widely used product for thermal solutions. Following are some reasons why it is so popular.

Characteristics Of Heat Sink

Good thermal and electrical conductivity

Low density (about 2.7kg/m³)

Low weight

High strength

Easy malleability

Easy machining

Excellent corrosion resistance

non-magnetic which avoids interference of magnetic fields

Easy to recycle

Aluminium VS Copper Heat Sink

1.Thermal Conductivity

Copper is more conductive than aluminum. In fact, aluminum only has 60% of the thermal conductivity of copper.

2.Weight

Aluminum accounts for only 30% of the density of copper. This means that the weight can be greatly reduced.

3.Cost

Aluminum is much cheaper than copper. In fact, its cost is about one-third. This can save a lot of cost.

How a Heat Sink Works

The heat sink must protect the electronic equipment and components from overheating. Therefore, they must be made of certain materials with good thermal conductivity.

Most devices that use power electronic equipment require a temperature-controlled environment. Otherwise, they are in danger of overheating, which may affect performance or, more seriously, become

a safety hazard.

Essentially, a heat sink profile is a way to dissipate any heat generated from a device or component. This requires an optimal speed to dissipate heat from the source at the same rate as the rate

at which the source generates heat.

In fact, optimization is the key to the success of any radiator system. This affects the choice of materials and basic aspects such as complexity, size, quality, and cost.

Therefore, while the selection of materials is crucial, other factors also need to be considered.

Where are aluminium heat sink profile Used For?

Commercial LED lighting

The heatsink extruded aluminium profile / aluminum heatsink extrusion profiles provides effective cooling for the LED (Light Emitting Diode) light source. These radiators are very small and can be

mass produced.

Circuit board & PCB (PC board)

By providing a precise combination of vertical and horizontal cooling, aluminum heat sink extrusions provide an effective thermal management process for circuit boards and PCBs. Various thicknesses

and customized forms are also easy to achieve.

Electronic instrument or electronic equipment:

The radiator is an indispensable device for electrical appliances, which can effectively dissipate the heat of the output transistor.

Automotive equipment, NEV (New Energy Vehicle)

The radiators used in automotive electronic equipment enable high-density components to operate at stable temperatures under a wide range of environmental conditions.

The purpose of the heat sink is specifically designed to extract heat from the components in the electronic device. The radiator is generally polished, and in most cases, it can be anodized or

powder coated to improve surface protection and corrosion resistance.

Choose Otalum for Extruded Aluminum Heat Sink Profiles

Otalum is one of the leading manufacturers of aluminum extrusion heat sink profiles in China. They specialize in producing high-quality aluminum extrusion heat sink profiles that are used in a wide

range of industrial and commercial applications. Their extruded aluminum heat sink profiles are designed to efficiently dissipate heat from electronic components, such as microprocessors, power

transistors, and LED lights.

Otalum's expertise in aluminum extrusion technology allows them to produce customized aluminum extrusion heat sink profiles to meet specific design and thermal requirements. Their advanced

manufacturing processes ensure that each extruded aluminum heat sink profile is precision-made to exact specifications, ensuring optimal performance and reliability.

With years of experience in the industry, Otalum has established a reputation for producing high-quality aluminum extrusion heat sink profiles that meet the highest standards of quality and

performance. They offer a wide range of aluminium extrusion heat sink profiles in various shapes, sizes, and finishes to suit the needs of their customers.

In addition to their expertise in manufacturing aluminum extrusion heat sink profiles, Otalum is committed to providing excellent customer service and support. They work closely with their

customers to understand their needs and provide personalized solutions to meet their specific requirements.

Overall, Otalum is a trusted and reliable source for high-quality extruded aluminum heat sink profiles, and their commitment to excellence and customer satisfaction makes them a leader in the

industry.

Otalum is a leading aluminum profile extrusion factory, of customed all aluminium profile products in Southeast-China.

- Country: China (Mainland)

- Address: Room 3/22, COFCO Group Center, Baoan District, Shenzhen, Guangdong Province, China

- Contact: Otalum