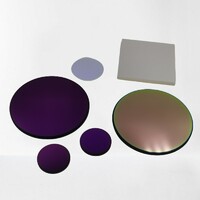

Float Window

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

While floating through the molten tin, the combination of gravity and surface tension results in smooth and flat surfaces on both sides.

a) Smooth and flat surface and good vision.

b) Excellent optical performance.

c) Stable chemical properties.

d) Resistant to acid, alkaline, and corrosion.

Specification of Float Window

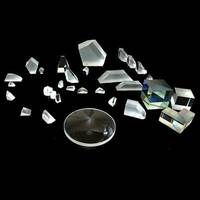

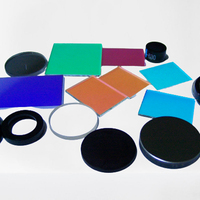

Optical windows are an essential component of many optical systems, including lasers, cameras, telescopes, and microscopes. They allow light to enter or exit an optical system while providing a

barrier to dust, moisture, and other contaminants. There are various types of optical windows available, including sapphire, quartz, and borosilicate glass.

Advantages of Float Glass Optical Windows

Float glass optical windows offer several advantages that make them highly advantageous for various applications. Here are some key advantages of float glass optical windows:

High Optical Clarity: Float glass optical windows have excellent optical properties, providing high transmission of light across a wide range of wavelengths. They offer minimal distortion, allowing

for accurate and clear imaging, making them suitable for applications in optics, imaging, and display technologies.

Smooth and Flat Surfaces: Float glass manufacturing process ensures that the windows have smooth and flat surfaces, free from distortions or imperfections. This enables precise light transmission

and minimizes scattering or aberrations, making them ideal for applications that demand high optical quality.

Mechanical Strength and Durability: Float glass optical windows exhibit mechanical strength and durability. They can withstand mechanical shocks, thermal stress, and environmental factors, making

them suitable for use in challenging industrial and outdoor environments.

Cost-Effective: Float glass manufacturing is a highly efficient and cost-effective process, allowing for large-scale production of optical windows at a relatively low cost. This makes float glass

optical windows a cost-effective solution compared to other types of optical materials.

Versatility: Float glass optical windows are highly versatile and can be customized in terms of size, shape, and thickness to meet specific application requirements. They can also be easily

integrated into different optical systems and setups.

Easy Handling and Processing: Float glass optical windows are easy to handle and process due to their flat and uniform surfaces. They can be easily cut, shaped, and polished according to specific

needs, simplifying the fabrication process.

Overall, the advantages of float glass optical windows make them a popular choice for a wide range of applications in industries such as optics, imaging, displays, lasers, and industrial systems.

Applications and Selection Criteria of Float Glass Optical Windows

Float glass optical windows, made from high-quality, flat glass, have a wide range of applications in various industries. Here are some common applications and selection criteria for float glass

optical windows:

Optics and Imaging: Float glass optical windows are used in optics and imaging systems, such as cameras, telescopes, microscopes, and spectroscopy devices. They provide a clear and smooth surface

for optical transmission, allowing for accurate imaging and light transmission.

Display Technology: Float glass optical windows are used in electronic displays, LCD screens, and touchscreens. They provide a protective cover, allowing for optimal viewing and touchscreen

functionality while maintaining durability and scratch resistance.

Laser Technology: Float glass optical windows are utilized in laser systems and applications. They help in shaping and directing laser beams, providing transmission of specific wavelengths, and

offering thermal insulation.

Industrial Applications: Float glass optical windows find application in various industrial settings, such as machine vision systems, barcode scanners, inspection equipment, and laser processing

systems. They provide robustness, optical clarity, and resistance to environmental factors.

Selection criteria for float glass optical windows include:

- Optical Transmission: Optical windows need to have high optical transparency and low absorption to ensure minimal loss of light during transmission.

- Surface Quality: The surface quality of the window should be smooth and free from defects, scratches, or blemishes to prevent distortion or interference with optical clarity.

- Mechanical Durability: Float glass optical windows should have mechanical strength and resistance to abrasion, impact, and thermal stress to withstand harsh environments and handling.

- Chemical Resistance: Depending on the application, resistance to chemical exposure or corrosion may be necessary.

- Size and Thickness: The size and thickness of the window should be chosen based on the specific optical requirements and structural constraints.

Consideration of these selection criteria ensures that float glass optical windows are chosen appropriately for their intended applications, resulting in optimal performance and durability.

Manufacturing Process of Float Glass Optical Windows

Float glass optical windows are manufactured using the following process:

Raw materials, including silica sand, soda ash, limestone, and dolomite, are mixed and melted in a furnace at a temperature of around 1500°C.

The molten glass is then poured onto a bed of molten tin, forming a uniform layer of glass that is cooled gradually.

The cooled glass is then cut into the required sizes and shapes using diamond-tipped tools.

The optical windows are then polished to achieve the required surface quality.

Cleaning and Maintenance of Float Glass Optical Windows

Float glass optical windows require proper cleaning and maintenance to ensure their long-term performance. Here are some tips for cleaning and maintaining float glass optical windows:

Cleaning

Use a soft, lint-free cloth or a microfiber cloth to clean the optical window. Avoid using paper towels or abrasive materials, as they can scratch the surface of the window.

Apply a small amount of a gentle cleaning solution, such as isopropyl alcohol or lens cleaning solution, to the cloth.

Gently wipe the surface of the optical window in a circular motion, starting from the center and moving towards the edges.

Use a dry cloth to remove any remaining cleaning solution.

Maintenance

Store the optical windows in a clean, dry environment to avoid contamination and damage.

Inspect the float glass optical windows regularly for any signs of damage or wear, such as scratches or cracks.

Handle the optical windows with care, using gloves or other protective equipment to avoid fingerprints or smudges.

Avoid exposing the optical windows to extreme temperatures or humidity, as this can affect their optical properties.

TC Optics as one of the most professional optical components suppliers, we provide cheap optical components, dielectric mirror for sale, windows in optical fiber communication, optical window in

optical fiber communication, calcium fluoride window, caf2 window, custom optical manufacturing and etc. Contact us to know more.

- Country: China (Mainland)

- Address: No. 1567 Liu Ying Lu, Kuan Cheng District, Chang Chun,P.R. China

- Contact: Aamina Gao