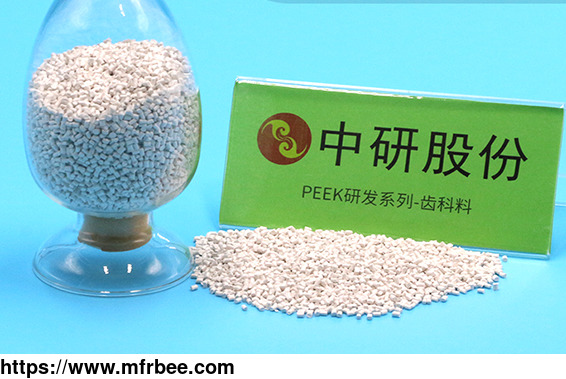

Dental Tooth Materials PEEK R&D Series

Specifications

Dental peek material R&D Series has good wear resistance and high mechanical strength. It is mainly used in dentistry in medical field.

Specification of Materials PEEK Teeth R&D Series

Material Properties Test Method Conditions Units 770G

Mechanical Data

Tensile Strength ISO 527 B reak,23℃ MPa -

Y ield,23℃ MPa 100

Tensile Elogation ISO 527 Break,23℃ % 45

Flexural Strength ISO 178 Break,23℃ MPa -

Y ield,23℃ MPa 165

Fleoural Modulus ISO 178 23℃ Gpa 4.1

Compressive Strength ISO 604 23℃ MPa 125

Charpy Impact Strength ISO 179/leA Notched kJm-2 7

ISO 179/IU Unnotched kJm-2 -

Izod Impact Strength ISO 180/A Notched kJm-2 7.5

ISO 180/U Unnotched kJm-2 -

Mould Shrinkage ISO 294-4 Along flow % 1

Across flow % 1.3

Thermal Data

Melting Point ISO 11357 ℃ 343

Glass Tansition (Tg) ISO 11357 Onset ℃ 143

Special Heat Capacity DSC 23℃ kj kg-1℃-1 2.2

Coefficient of Thermal Expansion ISO 11359 Along flow below Tg ppm K-1 45

Along flow above Tg ppm K-1 120

Heat Deflecion Temperature ISO 75A-f 1.8Mpa ℃ 152

Thermal Conductivity ASTM C177 23℃ W m-1K-1 0.29

Flow

MeltIndex ISO 1133 380℃,5kg g10min-1 10

Miscellaneous

Density ISO 1186 Crystalline gcm-3 1.3

Amorphous gcm-3 1.26

Shore D Hardness ISO 868 23℃ 85

Water Absorption(3.2mm thick Tensile Bar) ISO 62-1 24h,23℃ % 0.07

by immersion Equilib riu m,23℃ % 0.4

Electrical Data

Dielectric Strength IEC 60243-1 2mm kV mm-1 23

Comparative Tracking Index IEC 60112 V 150

Dielectric Constant IEC 60250 23℃,1kHz 3.1

23℃,50kHz 3

Loss Tangent IEC 60250 23℃,1MHz 0.004

Volume Resistivity IEC 60093 23℃,1V Ω cm 10 16

275℃ Ω cm 10 9

As one of peek suppliers, we can also offer sorts of peek removable denture for sale, if you have needs, please contact us.

If you want to know more about peek in dentistry ppt, please visit our website.

Zhongyan (ZYPEEK) is a leading polyetheretherketone peek raw material manufacturer, providing types of natural peek material. Our polyetheretherketone PEEK raw materials are widely used in profile,

medical, wire & cables, energy development, and transportation.

- Country: Afghanistan

- Address: No.1177, Zhongyan Road,Luyuan Economic Development Zone,Changchun, Jilin,Province ,China 130113

- Contact: miss shen