Chain Hooks

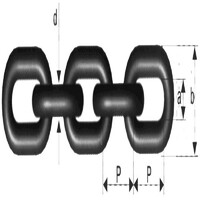

Specifications

Chain Hooks

As one of chain hooks manufacturers, TITANSUHE has a huge range of chain hooks for Rigging and Tie Down. All our chain hooks are made of alloy steel with heat treatment for high strength and

abrasion resistance that grade to 80 and 100, rated for overhead lifting applications. We also have grade 43 and Grade 70 chain hooks to help you build your lashing and tie down system. For

different rigging purpose, we have sling hooks, grab hooks, self-locking hooks, foundry hooks, container hooks, lifting chain components etc for your choice. These hooks can come with eye type,

clevis type or swivel type. Eye type chain hooks are designed for permanent attachment which have higher safety. Clevis type chain hooks are structured with a sturdy pin which can passes directly

through the end link of chain. This greatly improve the assembly efficiency and save your rigging cost. Swivel hooks can rotate 360 degrees which provide easy access and attachment to the loads.

You can find below chain hooks from us.

In Which Occasions, The Chain Hook Should Be Scrapped?

The hook shall be scrapped under any of the following conditions:

① Cracks by visual check;

② The wear of dangerous section reaches 10% of the original size;

③ Hook opening is 15% more than the original size;

④ The torsional deformation of hook body exceeds 10 °;

⑤ Plastic deformation of the dangerous section of the hook or the neck of the hook;

⑥ The hook thread is corroded;

⑦ Replace the bushing when the wear of the hook bushing reaches 50% of the original size;

⑧ When the wear of the disc hook mandrel reaches 5% of the original size, the mandrel shall be replaced.

Still not find the chain hooks you want, you can contact Titansuhe lifting equipment factory for more custom solutions.

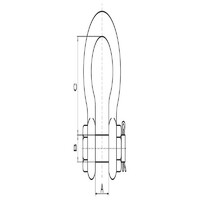

Dangerous Section of The Chain Hook

All the chain hooks have three dangerous sections, which should be paid special attention during inspection. As shown in the below schematic diagram, the three dangerous sections of the chain hook

are:

(1) On the one hand, section A-A is affected by the tension of the sling, and the hook tends to be straightened; On the other hand, it is also affected by bending moment. Because the bending moment

acting on this section is the largest and the bending stress is the largest, this section is a dangerous section.

(2) Section B-B is the same as section A-A. section B-B tends to be straightened and cut under the action of sling tension. The shear stress here is the largest, so it is also a dangerous section.

Schematic diagram of dangerous section

Schematic diagram of dangerous section

(3) C-C section, which is the thinnest part of the hook column, tends to be pulled off under the tension of the sling. The tensile stress here is the largest, so it is also a dangerous section.

Chain Hook Safe Use Tips

The lifting chain hook should be manufactured by a professional factory according to the technical conditions and Safety specifications of EN1677 or equivalence, and all the chain hooks should be

tested and supplied with quality certificate. Otherwise it is not allowed to be used.

The new hook shall be subject to load test, and the opening of the measured hook mouth shall not exceed 0.25% of the original opening.

During use, the hook shall be checked frequently for cracks, serious deformation, corrosion and wear

The hook shall be tested once a year. During the test, conduct a 10min static test at 125% of the rated working load, and check with a MPI or other methods. There shall be no cracks, cracks and

residual deformation.

The three dangerous sections shall be cleaned with kerosene and checked for cracks with a magnifying glass. Check the wear of bushing and pin for plate hook.

Defects on the hook shall not be repaired by welding

There are many lifting equipment manufacturers in China, but we are one of the best choices for you.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia

- Founded Year: 2005

- Address: 8-3, A Tower, Xiexing Building, No.59, Hongjin Road, Yubei District, Chongqing, China

- Contact: TITANSUHE TECH