FOOD STEAMER STAINLESS STEEL BELT LASER WELDER

Product Quick Detail

- FOB Price

- USD $800,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Ningbo

- Packaging

- Standard export packaging

- Delivery

- 30 Days

Specifications

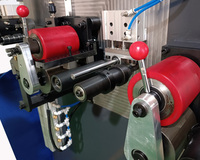

The equipment is mainly an industrial laser welding machine designed for steamer and other products. According to the characteristics of the stainless steel width and thickness of the steamer and

other products, the equipment adopts the most advanced continuous industrial laser welding technology in China. welding. The equipment has a beautiful appearance, and the fuselage structural

accessories are made of world-renowned brand products such as AirTAC, Delta, and Omron.

THE PARAMETER OF FOOD STEAMER STAINLESS STEEL BELT LASER WELDER

Rated total power Input voltage Enter the frequency Product diameter Product thickness Product width Dimensions

25KW 3*380V 50HZ 120~600mm <0.7mm 25~118mm 1800*1700*2100mm

The Application Of Food Steamer Stainless Steel Belt Laser Welder

The equipment is mainly used for the welding of stainless steel strips of the food steamer. The equipment adopts high-precision servo motor feeding, high-speed start-up clamping, pushing, cutting,

and precise welding. The surface of the welded product is very smooth, achieving a seamless welding effect, and the desoldering rate is less than 0.1%.

The Advantages Of Food Steamer Stainless Steel Belt Laser Welder

The food steamer stainless steel belt laser welding machine adopts the continuous laser welding method, the equipment operation is simple, and the operation parameters are controlled by the touch

screen, which can automatically complete multiple processes such as feeding, cutting, welding, and unloading. The width of the steel strip can be adjusted arbitrarily, no need to replace the mold,

no consumables for processing, saving processing costs and reducing energy consumption.

Other Notes Of Food Steamer Stainless Steel Belt Laser Welder

Food Steamer stainless steel belt laser welder Main Characteristics

The product has no creases, the scratch length is 5mm, and the depth is less than 0.01mm.

Fast speed, 10~20 pieces can be welded per minute.

Welding thickness, the thickest product can weld stainless steel with a thickness of 1.5mm.

High configuration, the configured material rack can bear the weight of 300kg.

Welding width, the maximum width of the product can be welded 190mm.

Large diameter, the diameter of products that can be welded by the equipment can reach 650mm.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2019

- Address: No. 28 Jinteng Road, Wuxiang, Yinzhou District, Ningbo

- Contact: ningboxihe com