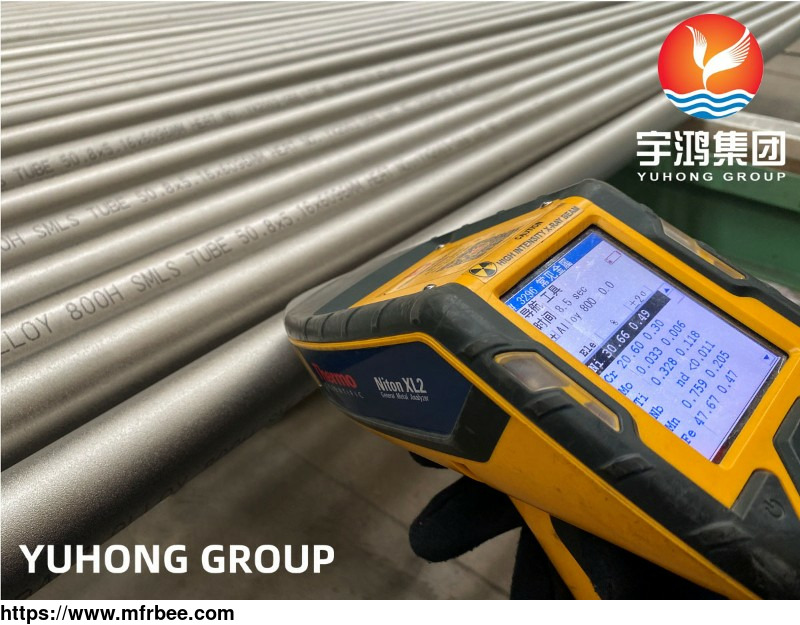

INCOLOY 800H/N08810 NICKEL ALLOY PIPE/TUBE

Specifications

Incoloy 800H pipe is a slightly modified version of Incoloy 800 with the 800H grade possessing higher creep and rupture strength. The modification of incoloy alloy 800H pipe is possible because of

the closely controlled carbon content and modified heat treatment.

INCOLOY ALLOY 800H PIPE EQUIVALENT SPECIFICATION

Country Body Grade

USA UNS N08800

France AFTER Z8NC 32.21

GB BS NA 15

Germany DIN 1.4876

INCOLOY ALLOY 800H PIPE PHYSICAL PROPERTIES

Properties Metric Units

Density 7,940 kg /m3 @ 20℃

Melting Range 1357-1385. ℃

Electrical Resistivity 0.989 micro-ohm. m @ 20℃

Specific Heat 460y / kg. ℃@ 20℃

Mean Coefficient of Expansion 14. 4x10 / ℃ @ 20℃

Thermal Conductivity 11. 5W / m. @ 20℃

Curie Temperature -115℃

Modulus of Elasticity

Tension 196.5 Gpa @ 20℃

Torsion 73.4 Gpa @ 20℃

Poisson's Ratio 0 . 339 @ 20℃

INCOLOY ALLOY 800H PIPE CHEMICAL COMPOSITION

Element Incoloy 800 Incoloy 800H Incoloy 800HT

Nicke 30.00-35.00 30.00-35.00 30.00-35.00

Chromium 19.00-23.00 19.00-23.00 19.00-23.00

Iron 39.50 min 39.50 min 39.50 min

Carbon 0.10 max 0.10 max 0.10 max

Aluminum 0.15-0.60 0.15-0.60 0.25-0.60

Titanium 0.15-0.60 0.15-0.60 0.25-0.60

Aluminum + Titanium 0.30-1.20 0.30-1.20 0.30-1.20

ASTM Grain Size Not Specified 5 or Coarser

INCOLOY ALLOY 800H PIPE MECHANICAL PROPERTIES

Incoloy 800H/N08810 Nickel Alloy Pipe/Tube Yield Strength Tensile Strength Elongation

Mpa Mpa %

Incoloy 800, 800H, 800HT Hot Finished Annealed 170 450 30

Incoloy 800 Cold Worked. Annealed 205 520 30

INCOLOY ALLOY 800H PIPE HIGHLIGHTS

Incoloy 800H(UNS N08810) pipe has a restricted carbon content range of 0.05 to 0.10%, which is in the upper portion of that of Incoloy 800 tube and is annealed at 1149 to 1177℃ (Incoloy 800 is

annealed at 983 to 1038℃). These differences impart Incoloy 800H pipe to have higher stress rupture and creep properties than Incoloy 800.

As a ss pipe manufacturer, we can offer sorts of related products for sale, if you have needs, please contact us.

- Country: Afghanistan

- Business Type: Manufacturer

- Market: Oceania

- Address: Room 1005--1007, No.1 New World Building, NO.1018 Min'an Road, Yinzhou District, Ningbo, China

- Contact: YUHONG .com