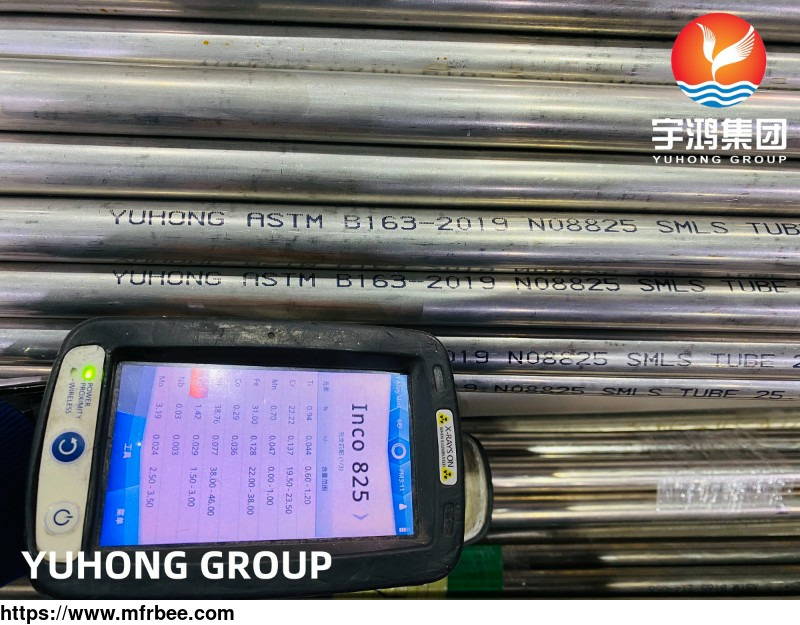

INCOLOY 825/N08825 NICKEL ALLOY PIPE/TUBE

Specifications

Incoloy 825/UNS N08825 seamless pipe uses nickel-iron-chromium alloy with additions of molybdenum and copper. The chemical composition of the Incoloy 825 tube is designed to provide exceptional

resistance to many corrosive environments.

INCOLOY ALLOY 825 SEAMLESS PIPE SPECIFICATION

Rod Sheet Strip Pipe Wire Fittings

ASME SB408 ASTM A 240/A480 ASME SB409 ASTM B 163, ASME SB 163 ASTM B408 & ASTM B 564 ASTM B366

ASME SB564 ASME SA 240/SA 480 ASME SB906 ASTM B 407/B 829, ASME SB407/SB 829 ASME Code Case1325 ASME SB366

BS3076 NA15 ASTM B409/B906 ASME Code Case 1325 ASTM B514/B 775, ASMESB 514/SB 775 ASME Code Case1949

BS3075 NA15 BS 3072NA15 ASME Code Case 2339 ASTM B 515/B 751, ASME SB 515/SB751 IS0 9723

SEW 47 BS 3073NA15 ASME Code Case 1325 and 1983, BS3074NA15. SEW 470 IS0 9724

Vdtuv 412 8434, DIN 17460, EN 10095 SEW 470, Vdtuv 412& 434, DIN 17460EN 10028-7 & EN10095 Vdtuv 412 & 434, ISO 6207. DIN 17459 IS09725

INCOLOY 825 MATERIAL MECHANICAL PROPERTIES

Alloy state Tensile strength N / mm2 Yield strength PO 2N / mm2 Elongation 5% Brinell hardness HB Max

N08825 Hot Finished 517 172 30 200

N08825 Cold Finished 586 241 30 300

INCOLOY 825 MATERIAL PHYSICAL PROPERTIES

Incoloy 825 Pipe, Alloy 825 Tubing Physical properties

Density / Specific Gravity 8.1 kg / dm3

0.30 Ib / in3

Melting point 1370-1400℃

ALLOY 825 TUBING HIGHLIGHTS

Incoloy 825 tube, incoloy 825 pipe is similar to alloy 800 pipe but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to

stress-corrosion cracking, and to localized attacks such as pitting and crevice corrosion. Alloy 825 tubing is especially resistant to sulfuric acids and phosphoric acids. The Incoloy 825 seamless

pipe using nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

If you want to know more kinds of stainless tubes, please visit our website.

- Country: Afghanistan

- Business Type: Manufacturer

- Market: Oceania

- Address: Room 1005--1007, No.1 New World Building, NO.1018 Min'an Road, Yinzhou District, Ningbo, China

- Contact: YUHONG .com