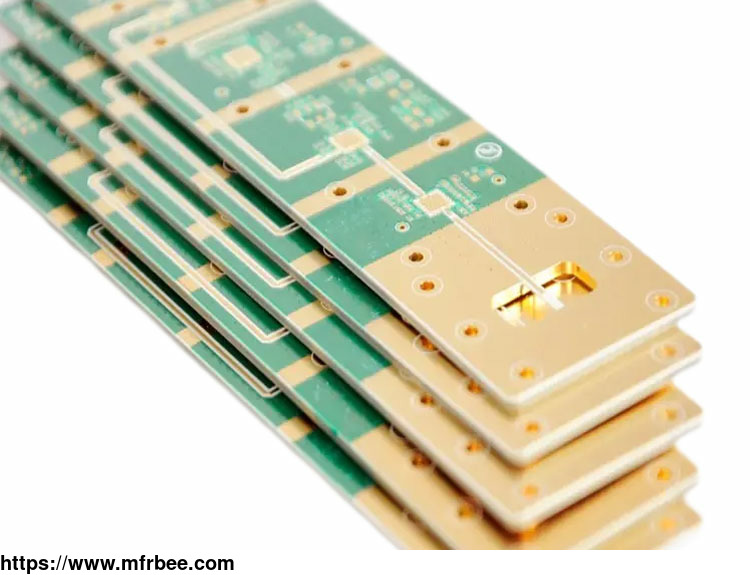

Heavy Copper PCB

Specifications

PCBs with a copper thickness of more than 70um are called thick copper PCBs, sometimes also called thick copper PCBs. Copper thickness typically varies from 105 to 400 µm. The thicker the copper,

the higher the power dissipation of the board. These thick copper plates are used for high current output and improved thermal management. Thick copper makes it possible to create boards with

cross-sections for high current loads, which also facilitates heat dissipation. Greenstone is one of the China heavy copper pcb heavy copper pcb manufacturers which can provide the most

professional products and services.

Advantages of China Heavy Copper PCB

Thick copper PCB is widely used in

various household appliances

high-tech products

military

medical

other electronic equipment.

The application of thick copper PCB makes the core component of electronic equipment products-circuit boards have a longer service life, and at the same time it is very helpful to the size

reduction of electronic equipment.

Greenstone Heavy Copper PCB Manufacturing Capabilities

Feature Capability

Material FR-4 Standard Tg 140°C, FR4-High Tg 170°C

Min. Track/Spacing For External layers:

4oz Cu 10mil/13mil,5oz Cu 12mil/15mil,6oz Cu 15mil/15mil,

For Internal layers:

4oz Cu 8mil/8mil,5oz Cu 10mil/10mil,6oz Cu 12mil/12mil

Min. Hole Size 0.15 ~ 0.3mm

Max Outer Layer Copper Weight (Finished) 8oz

Board Thickness 0.6-6mm

Surface Finishing HASL lead free, Immersion Silver, Immersion gold, OSP, Hard Gold.

Solder Mask Green, Red, Yellow, Matte Black, Matte green, Blue, White, Black

Silkscreen White, Black

Via Process Tenting Vias, Plugged Vias, Vias not covered

Testing Fly Probe Testing, fixture test and A.O.I. testing

Build time 5-15 working days

Lead time 3-5 working days

As a contract electronics manufacturing factory, we can offer sorts of circuit board assembly for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Founded Year: 2011

- Contact: green pcba