Hydraulic And Pneumatic Parts

Specifications

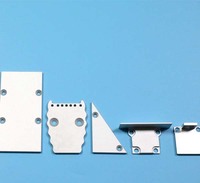

Hydraulic And Pneumatic Parts

Sibai produced a lot of mechanical hydraulic and pneumatic system components, from CNC machining and CNC Lathing, with strict tolerance control. We ensure fast production and sured delivery.

Sibaicnc provide hundreds of hydraulic and pneumatic housings according to customers' needs. Some housings are used for pneumatic special cylinders and telescopic cylinders. These cylinders are

not only used in the textile, packaging and printing machine industries, but also in chemical, food and pharmaceuticals plants.

Specificatoin of Production

Name: Customized Precision CNC Machinined Hydraulic and Pneumatic Parts

Material: Stainless steel 316, 304, Aluminium 6061

Processing: Investment casting, CNC turning, CNC turning-milling compound, CNC machining

Needed Machines Automatic feeding 46 Gang Tooling lathe, Single-piece Turret lathe with spindle, CNC turning-milling machine, CNC 3-axis machining center, CNC 5-axis machining center, CNC

Swiss-type automatic Lathe, Drilling and Tapping machine

Surface treatment: blank, ultrasonic cleaning, sandblasted anodizing

Place of origin: Dongguan, Guangdong, China(Mainland)

MOQ: 10 pcs

Lead time: samples in 7-15 days

Delivery: UPS, DHL, TNT, FedEx; airway or oceanshipment

Sibai Hydraulic And Pneumatic Components

The processing sequence is the key. It’s very important to ensure the exact dimensions, especially for the side holes. We process the side holes after brush finishing. We need to custom the special

clamp for the CNC lathe process to do these side holes. The most difficult process is the measurement control on the fine holes during the anodizing. We plug holes to control the fine hole

dimension to be exact during the anodizing. It is a successful way.

We need to check and control the tolerance during the CNC Lathing process. We also need to test the fine holes dimensions during the anodized process. Although the whole process are complex and

difficult, the customers’ recognition and appreciation are the best encourage for us.

These housings can be made by aluminium, brass or a wide variety of stainless steel. Most of these hydraulic and pneumatic housings we provide are made from EN AW 6061. The surface treatment we

provide is sandblasting and nature anodizing. The sizes are different, like from 30mm×30mm×56mm to 40mm×40mm×260mm. To meet the high and good sealing requirement of the hydraulic and pneumatic

housings, we need to ensure the exact tolerance for the holes. We also need to deburr carefully. If the burrs are not cleaned completely, it will directly affect the sealing function and assembly.

The process of these hydraulic and pneumatic housings are complex and difficult. So, generally it takes longer processing time, and the delivery period is a bit longer. The quantity we can provide

from hundreds to thousands per batch of order.

Now, Sibai has much experience on these kinds of hydraulic and pneumatic housings. Customers are also satisfied with these housings made by Sibai. So, customers are glad to place annual order for

these housings directly to Sibai.

- Country: China (Mainland)

- Address: No. 2, Dantang Road, Daping, Tangxia Town, Dongguan, 523722, China.

- Contact: SI BAI