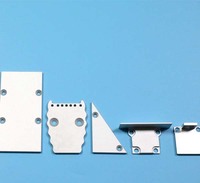

Stamped Stainless Sheet Metal Processing Parts

Specifications

Stamped Stainless Steel Sheet Metal Parts

Sibai provides stamping processing on different metal materials, especially from steel and stainless. Sibai design and produce stamping tools, to realize complex parts. Sibai has different Tons of

stamping machines. The thickness for stainless steel can be up to 6 mm.

Specificatoin of Stamped Stainless OEM Sheet Metal Stamping Parts

Name: Customized Precision Stainless Steel Sheet Metal Processing Parts

Material: V2A, AISI 304 (1.4301,X5CrNi18-10) AISI 303 (1.4305, X8CrNiS18-9)

V4A AISI 316 (1.4401), AISI 316L (1.4404) AISI 316Ti (1.4571),

1.4310, A2, etc.

Processing: laser cutting, Stamping, bending, welding, fastening

Needed Machines Stamping machine, laser cutting machine, tapping machine

Surface treatment: galvanized (galvanisch verzinkt)

blue zinc plated, (verzinkt blau passiviert, Fe//Zn 12//C, Cr-VI frei,DIN 50961-Fe Zn 8 B)

yellow zink (gelb verzinkt)

powder coated (pulverbeschinchtet)

blackened (brüniert)

KTL, gas nitrided (gasnitriert), Phosphating etc.

mirror polished (gleitgeschliffen)

satin polished (powder coated (pulverbeschinchtet)

Place of origin: Dongguan, Guangdong, China (Mainland)

MOQ: 50 pcs

Lead time: samples in 7-10 days

Delivery: UPS, DHL, TNT, FedEx; airway or oceanshipment

Sibai Stainless Steel Pressed Sheet Metal Components Features

Sibai uses the following equipment to process stainless steel sheet metal, shearing machine, laser cutting machine, punching machine, bending machine,and folding machine.

Sibai can provide stainless steel sheet metal thickness up to 6 mm, and steel plate up to 10 mm.

There are several ways to work out the sheet metal:

a. Shearing machine cutting: to use the shearing machine to cut out the shape, length and width of the unfolded drawing.

b. Punching: to use the punching machine to punch the flat part structure after the parts are unfolded on the plate in one or more steps. It has the advantages of short labor time, high efficiency,

and reducing processing costs.

c. Laser cutting: to use laser cutting machine to cut the structure and shape of its flat parts from the stainless plate.

To finish the products, we need the rest processings:

1. Pressure riveting: Pressure riveting studs, pressure riveting nuts, pressure riveting screws are often used. The pressure riveting method is generally completed by a punch or hydraulic riveting

machine, and it is riveted to the sheet metal parts.

2. Bending: Bending is to fold 2D flat parts into 3D parts. Its processing requires a bending machine and a corresponding bending die to complete the operation. It also has a certain bending

sequence.

3. Welding: Welding is to weld multiple parts together to achieve the purpose of processing or to weld the side seam of a single part to increase its strength. Sibai often adopts tungsten inert gas

welding (TIG) to weld them for assembly.

4. Surface treatment: for most of stainless steel sheet metal parts, there’s no surface treatment asked. But some stainless steel needs brushing surface before processing.

5. Assembly: It is to assemble multiple parts or components together in a certain way to make them a complete material, such as welding, fastening.

One of the things to pay attention to is the protection of the material, not scratches and bumps. Assembly is the last step in the completion of an item. If the item cannot be used due to scratches

and bruises, we have to rework, which will waste a lot of processing time and increase the cost. Therefore, we must pay special attention to the protection of materials.

As one of precision metal stamping parts suppliers, we can offer sorts of metal sheet stamping parts for sale, if you have needs, please contact us.

Dongguan Sibai Metal Works Limited, located in Dongguan China, focuses on customized drawing-designed CNC machining and CNC precision mechanical part fabrication since 2006. After near 20 years

development, Sibai has become a supplier with comprehensive capabilities in the field of mechanical metal and plastic processings. The customized precision metal components Sibai made are mostly

ordered by European and American industrial enterprises.

If you want to know more kinds of precision machining service, please visit our website.

- Country: China (Mainland)

- Address: No. 2, Dantang Road, Daping, Tangxia Town, Dongguan, 523722, China.

- Contact: SI BAI