SDS Steel Fiber

Product Quick Detail

- Minimum Order

- 100

- Place Of Origin

- Shandong Province,China.

- Packaging

- 20kg/bag,1ton/pallet,16tons/20' 22tons/40'

- Delivery

- 15-20 days

Specifications

There are many types of steel fibres used in concrete. The steel fiber for concrete reinforcement is a new kind of metal material, in order to enhance concrete with metal fiber and shotcrete in its

hardened state. Tengzhou SDS steel fibers make concrete have extremely high flexural strength and shear strength, and have good toughness, crack resistance, earthquake resistance, seepage control,

and other functions. Widely used in industrial factory floors, highways, high-speed rail, bridges, airports, tunnels, water conservancy, electric power, municipal engineering, etc. The company has

passed ISO9001 certification, and its products are exported to Southeast Asia, Europe, America and etc. Welcome to contact us for more information about steel fibers for concrete reinforcement.

Advantages of Loose Hooked End Steel Fiber

Technology advantage

The design of end hooks at both ends of steel fiber is the best anchoring design, which slowly deforms in the process of drawing, thus enhancing the binding force between hooked steel fiber and

concrete.

Material advantage

SDS hooked steel fibre is made of high-quality wire by cold drawing, and its tensile strength is greater than 1100MPa, which ensures extremely small tolerance and high tensile strength.

Economic advantage

A.Compared with ordinary concrete, the same mixing and construction, do not need to add equipment.

B.Under the same strength, the concrete consumption can be saved

C.Replace or partially replace reinforcement

E.Shorten the construction period, especially suitable for large projects requiring continuous and rapid pouring of concrete.

Advantage of Brass Coated Micro Steel Fiber

Performance Advantage

With good dispersion performance in concrete; less impact in UHPC Liquidity and high tensile strength.

Characteristic Advantage

Providing good impact, fatigue, shrinkage control, and ductility in all kinds of concrete.

Material Advantage

Significantly improve the toughness of concrete.

Advantages Of Glued Hooked End Steel Fiber

Performance Advantage

Improve the structural strength of concrete, impact resistance, wear-resistance and freeze-thaw resistance, as well as the durability.

Characteristic Advantage

Reduce crack widths and control the crack widths tightly.

Economic Advantage

Reduce steel reinforcement requirements.

The Formation of Steel Fiber

Steel fibers are defined in ASTM A820 as pieces of smooth or deformed fibers that are sufficiently small to be dispersed at random in a concrete mixture. ASTM A820 steel fibre reinforcement

designates tensile requirements, dimensions and permissible variations. There are mainly 4 steps for steel fibers based on our production process:

Raw Material

Dry Drawing

Glued

stampling & Forming

The Benefits of Steel Fiber

For the same mixing and construction, there is no need to add equipment or increase the construction cost of metal fibers for concrete due to the low steel fibre cost.

Under the same strength requirement, metal fibers for concrete can replace steel mesh and reduce the pouring thickness of concrete by 15-25%.

Improve the construction conditions, mixing vehicles and construction personnel can reach the site directly, and shorten the construction period by 30%. Steel fiber reinforced concrete has high

tensile strength, which can prolong the distance between contraction joints and facilitate continuous and rapid pouring of concrete.

Convenient construction, saving labor, greatly shortening the construction period and saving the total steel fibre cost.

The Working Principle of Steel Fiber

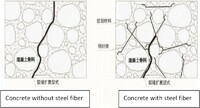

The working principle of steel fibers for concrete reinforcement involves reinforcing the concrete matrix in three dimensions using steel fibers. These metal fibers, with their specific tensile

strength, aspect ratio (length/diameter), and anchorage, play a crucial role in enhancing concrete performance.

By being distributed throughout the concrete, steel fibers effectively restrain the formation of micro-cracks and help redistribute the accumulated stress resulting from applied loads and

shrinkage. When cracks do occur, the steel fibers intercept them promptly and inhibit their growth, significantly reducing the likelihood of further crack propagation. This proactive approach

ensures that the concrete remains strong and durable, minimizing the risk of structural failure.

FAQs of Steel Fiber

What is steel fiber reinforced concrete?

Fiber reinforced concrete is comprised of hydraulic cements containing fine and course aggregatea and fiber. A super-plasticizer is ofter used to enhance the mix workability. Fiber products are

available in a variety of types and sizes. The underlying principle however on all fiber reinforced concrete is to provide discoutinuous reinforcement and effective crack control.

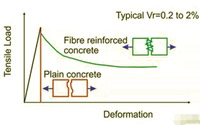

How do fiber work?

Fibers reinforce in three fimensions throughout the entire concrete matrix. Fiber performance is based on the combination of the tensile strength, aspect ratio(length/diameter)and anchorage. the

distributed fibers resrain micro-cracking and redistribute accumulated stress caused by applied loads and shrinkage. The earlier a crack is intercepted and its growth inhibited, the less chace it

will have develop.

What are the types of steel fibers used in concrete?

Types of steel fibre including:1.Straight 2.hooked 3.Crimped.4.Double duoform 5.ordinary duoform 6.paddied 7.enlarged ends 8.irregular 9.indented.

Is there a difference between Micro and Macro Synthetic Fiber?

Macro synthetic fibers are intended to carry a load and therefore, can be used to replace traditional reinforcement. Typical applicationss are: slabs on ground, shotcrete, precast and composit

metal deck applications. Macro synthetic fibers are also used to eliminate both early and long term cracking. Micro fibers are generally utilized to minimize early age plastic shrinkage cracking

and aggregate settlement that can occur within the first 24 hours.

As a steel fiber supplier, we can offer sorts of related products for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Founded Year: 2011

- Address: NO.397 Shunhe Road,Tengzhou Economic Development Zone,Shandong Province,China.

- Contact: cnsteelfiber