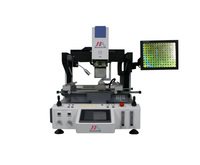

ZM-R7830A Smart Optical BGA Rework Station

Specifications

R7830A is an optical alignment automatic rework equipment. It also works as laser BGA SMD rework station, multi-language menu interface, automatic feeding device, X/Y AXI machine that can be controlled by joystick, fast and convenient operation, imported high-definition CCD (2 million pixels) optical alignment system, high Precision temperature control sensor system, precise temperature control.

As one of the most reliable laser BGA Rework Station manufacturers, Seamark ZM provides the best BGA rework station for motherboards with good quality.

Functions of R7830A Laser SMD Rework Station

01 X/Y/Z Axis Automatic Displacement

The top temperature zone of the Laser SMD Rework Station is controlled by the joystick control servo system, which can automatically move and align at fast

02 Vacuum Adsorption and Nitrogen Protection

The top heating head has a built-in vacuum suction nozzle for chip adsorption, electrically controlled 360-degree rotation alignment, with negative pressure monitoring and pressure protection device. The bottom temperature zone of the Laser SMD Rework ZM Station adopts a large-area heating wire layout, moves symmetrically with the top temperature zone, and can be connected with nitrogen to prevent PCBA from yellowing.

Features of R7830A Laser SMD Rework Station

Multilingual menu interface

Automatic feeding device

X/Y axis can be controlled by joystick, operation is quick and convenient

Imported high-definition CCD (2m pixels) optical alignment system.

High-precision temperature control sensing system.

As one of the top BGA Rework Station suppliers in China, Seamark ZM is famous for its rich technical force, complete detection means, reliable product quality, full service. If you want to know some different types of BGA repair machines and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

Specification Of ZM R7830A Laser SMD Rework Station

Power Supply AC380V±10% 50/60HZ

Power 7.15KW(Max), Top heater(1.45KW) Bottom heater (1.2KW), IR Preheater (4KW), Other(0.5KW)

PCB Size 565*467mm(Max); 6*6mm(Min)

BGA Chip Size 80*80mm(Max); 2*2mm(Min)

IR Heater Size 500*380mm

Motion Control X/Y/Z

Temperature Sensor 5 Pcs

Operation Method 8" HD touch panel

Control System Panasonic PLC + Temperature control module

Display System 15" HD industrial display ( 1080P 16:9)

Alignment System 2 Million Pixel HD digital imaging system, automatic optical zoom with laser red-dot indicator

Vacuum Adsorption Automatic

Alignment Accuracy ±0.01mm

Temperature Control K-type thermocouple closed-loop control with accuracy up to ±1℃

Feeding Device Yes

Positioning V-groove with universal fixture

Dimensions L810*W1100*H960mm

Weight 151KG

As an infrared rework station factory, we can offer sorts of related products for sale, if you have needs, please contact us.

If you want to know more kinds of x ray pcb inspection machine, please visit our website.

- Country: China (Mainland)

- Address: F2, Building 10, Huaide Cuihai Industrial Zone, Bao'an, Shenzhen

- Contact: Jackie Tian