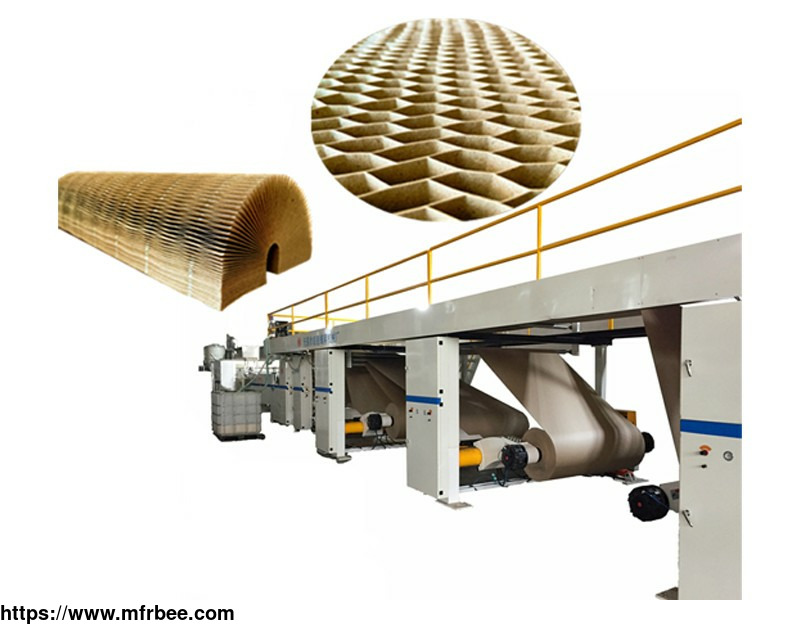

Honeycomb Paper Core Machine

Product Quick Detail

- FOB Price

- USD $10,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

The Paper honeycomb core machine includes 2 models. There are 7 parts: Heavy load hydraulic paper stand, Paper core gluing machine, Paper core conveying pressing machine, dryer, High-speed cutting

machine, Paper core conveying machine, and Electrical control cabinet. This paper honeycomb core machine can produce honeycomb paper cores in a one-stop manner. The production process starts from

the base paper to directly produce the cut honeycomb paper core. The introduction of foreign advanced technology of paper honeycomb core machines eliminates the need for paper cutters and butting

machines for the traditional production of honeycomb cardboard. The biggest advantage of the paper honeycomb core machine is high automation and low labor cost.

Types of Paper Honeycomb Core Machine

High Speed Paper Honeycomb Core Machine

Model: CX-2000 Type: Continuous type Length of the total line: 33m Power supply: 66kw Cutting speed: 0-720cuts/min

Normal Speed Honeycomb Paper Core Machine

Model: CX-1600 Type: Continuous type Length of the total line: 32m Power supply: 60KW Height of honeycomb paper: 6-100mm Cutting speed: 380cuts/min

Advantages of Honeycomb Paper Core Machine

The cutting precision of paper honeycomb core machine is high, and the speed is fast. From the raw paper in to the cardboard out, honeycomb paper core machine is completed at one time on a fully

automatic production line. Only 2 to 3 operators are required, the utilization rate of base paper is high, and the technology of honeycomb paper core machine is advanced. Our paper honeycomb core

manufacturers has high degree of automation, advanced technology, low loss, and touch screen operation. The operation of paper honeycomb core machine is simple and convenient for workers, and the

performance is stable and reliable. It is at the leading level in the domestic industry.

Features of San Machinery Honeycomb Paper Core Machine

Honeycomb paper core machine can produce two kinds of honeycomb paper with different cells. Two sets of honeycomb gluing mechanisms with different cell sizes (the cell size is determined by the

user) 4.5mm and 6mm paper glued simultaneously. Tooth rollers, gluing rollers, fine grinding, hard chrome plated surface, with umbrella size, seal ring for main gluing rollers. Each tooth roller

can be transverse adjusted to adjust the cell shape of honeycomb. The decorative board on the paper honeycomb core machine is raised, the sides are curved, the paper platform guardrail is raised.

Paper core is conveyed stably (Conveyor belt adopts NBR), which can adjust the frequency and speed individually on the paper honeycomb core machine. The honeycomb paper core machine is controlled

by PLC, and it can walk synchronously. Besides the running speed can be adjusted independently for each section. Electric cabinet is dustproof.

Applications of Honeycomb Paper Core Machine

Paper honeycomb core machine is widely used in packaging industry, transportation industry, making crafts or making honeycomb cardboard, etc. Honeycomb paper core has the characteristics of light

material and environmental protection.

As one of paper honeycomb core suppliers and paper honeycomb core manufacturers, we will do our best to meet all the needs of customers.

- Country: China (Mainland)

- Founded Year: 2005

- Address: No.33 Lianyungang Road, Qingdao, China

- Contact: san machinery