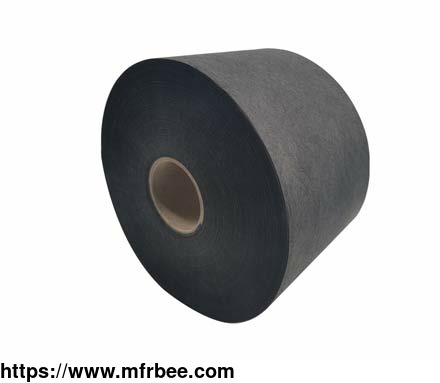

Medical Meltblown Nonwoven Fabric

Specifications

Medical meltblown non-woven fabrics are mainly used to filter micron particles such as dust, microorganisms, smog, etc., which can be called the heart of masks. Normally, the medical melt blown cloth is made up of polypropylene superfine fibers randomly distributed and bonded together, and the appearance is white, flat, and soft. The material fiber fineness is 0.3-7.0 microns.

Benefits of Medical Meltblown

Unique medical meltblown nonwovens material that meet the highest requirements for filtration, insulation and adsorption applications.After high-voltage electret electrostatic treatment, medical meltb...

Unique medical meltblown nonwovens material that meets the highest requirements for filtration, insulation, and adsorption applications. After high-voltage electret electrostatic treatment, medical melt-blown cloth has the characteristics of low resistance, high efficiency, high dust capacity, etc.

The random distribution of fibers provides more opportunities for thermal bonding between fibers, thus making melt blown The gas filter material has a larger specific surface area and a higher porosit...

The random distribution of the medical-grade meltblown nonwoven fabric provides more opportunities for thermal bonding between fibers, thus making melt-blown the main gas filter material that has a larger specific surface area and a higher porosity (≥75%).

The unique dense fine-denier fiber structure of the medical meltblown non-woven fabric increases the number and surface area of the fiber per unit area, and the voids are extremely fine. This physical...

The unique dense fine-denier fiber structure of the medical melt-blown cloth increases the number and surface area of the fiber per unit area, and the voids are extremely fine. This physical structure has a filtering effect of about 30%.

As a pp non woven fabric manufacturer, we will do our best to meet all the needs of customers.

- Country: China (Mainland)

- Business Type: 制造商

- Market: 美洲,欧洲,亚洲

- Founded Year: 1994

- Address: Phase 2, NBI Industrial Park, No. 5001-502, Sili Road, Guanlan Longhua District, Shenzhen City, Guangdong Province.

- Contact: canuxi -nbi